| Item | Machine Code | Call out |

| LCIT RT3030 | D696-27 (EU/AP) | 4 |

| Internal Shift Tray SH3070 | D691 | 8 |

| Bridge Unit BU3070 | D685 | 7 |

| 1 Bin Tray BN3110 | D692 | 6 |

| Side Tray Type M3 | D725 | 7 |

| Memory Unit Type B 32MB | G578 | - |

Fax Option Type M4 | D167-02 (EU) D167-03 (AP) | - |

| G3 Interface Unit Type M4 | D167-08 (EU/AP) | - |

| IEEE 802.11a/g/n Interface Unit Type M2 | D164-01 | - |

| Memory Unit Type M3 2GB | D164-03 | - |

Fax Connection Unit Type M4 | D166-02 (EU) D166-03 (AP) | - |

Postscript3 Unit Type M4 | D166-06 (EU) D166-07 (AP) | - |

| Camera Direct Print Card Type M4 | D166-13 | - |

Browser Unit Type M4 | D166-16 (EU) D166-17 (AP) | - |

| SD card for NetWare printing Type M4 | D166-19 | - |

IPDS Unit Type M4 | D166-21 (EU) D166-22 (AP) | - |

OCR Unit Type M2 | D166-26 (EU) D166-27 (AP) | - |

| Smart Card Reader Built-in Unit Type M2 | D739-06 | - |

| Imageable Area Extension Unit Type M3 | D739-07 | - |

| Marker Type 30 | H903 | - |

| ADF Handle TypeC | D593-81 | - |

| Item | Machine Code | Call out |

| IEEE 1284 Interface Board Type A | B679 | - |

| Bluetooth Interfance Unit Type D | D566 | - |

| File Format Converter Type E | D377-04 | - |

| Copy Data Security Unit Type G | D640 | - |

| Optional Counter Interface Unit Type A | B870 | - |

| Key Counter Bracket Type M3 | D739-09 | - |

| Card Reader Bracket Type 3352 | D593-61 | - |

| Unicode Font Package for SAP(R) 1 License | B869-01 | - |

| Unicode Font Package for SAP(R) 10 License | B869-02 | - |

| Unicode Font Package for SAP(R) 100 License | B869-03 | - |

| SD Card for Fonts Type D | D641 | - |

| DataOverwriteSecurity Unit Type H | D377-06 | - |

| Waste Toner Bottle MP C6003 | D860-01 | - |

| Color Controller E-22C | D730-01 (EU/AP) | - |

| Color Controller Connection Board Type M4 | D730-04 | - |

| External Keyboard Bracket Type M3 | D739-10 | - |

| Smart Operation Panel Type M3 | D148-83 (AP) | - |

SPECIFICATIONS

See "Appendices" for the following information:- General Specifications

- Supported Paper Sizes

- Software Accessories

- Optional Equipment

- Other Specifications

GUIDANCE FOR THOSE WHO ARE FAMILIAR WITH PREDECESSOR PRODUCTS

1.4.1 DIFFERENCES FROM PREDECESSOR

Scan, LD unit, Paper feed unit

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

Scan | LED Scanning on all models Non contact sheet-through scan (DF use) | 45/55 CPM halogen scan Contact sheet-through scan | Energy saving Improvement of black line occurrence |

LD unit | Adjustment of original point after the unit replacement

| Adjustment of original point after the unit replacement

| Serviceability improvement |

Paper feed | RF system Paper weight capacity:52 to 300g/m2 Draw system tray Up to SRA3 compatible (opt) Paper tray detection: Specific sensor Clicked operational feeling at position of regular paper size Double feed detection (D150 only) Small size standard support(2nd tray only) Paper dust case removable by technician | FRR system Paper weight capacity:52 to 256g/m2 Locked tray Up to A3 Paper tray detection: Paper size detection sensor No clicked operation feeling No double feed detection Small size tray option Paper dust case removable by technician | Simplify the layout Paper capability improvement User ability improvement Expand paper size User ability improvement User ability improvement Spec improvement |

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

Duplex / Exit | Duplex: 256g/m2 Internal tray reverse switch back system Jam detection LED(D148/D149/D150 only) Real time jam animation | Duplex: 169g/m2 Internal reverse system No Jam detection LED No real time Jam animation | Paper capacity up Down sizing User ability up User ability up |

By-pass | Side fence set assist function(D150 only) | No side fence set assist function | User ability up |

Driving | Individual motor for paper feed and transport (DC motor) | One motor for paper feed and transport (STP motor) + clutch | Energy saving and high productivity |

Frame | Baseless(stand by three points) Partially adopt for plastic frame | Frame with base | Less machine weight |

Air flow | Proper cooling system | Atmosphere cooling system | Cooling efficiency up |

PCDU

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

PCDU | Spring release procedure as each model needed at the unit replacement Harness connection Heat seal at machine installation and unit replacement | No spring release procedure Drawer connection Heat seal only at unit replacement | Optimization of PM yeild and compatible unit for each model Simplify the unit layout |

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

PCU:

| PCU:

| Downsizing | |

| Distance of PCU and | Distance of PCU and | Imrovement of | |

| PCU | Charger roller:

| Charger roller:

| charger roller |

| Lubricant application blade in | Lubricant application blade | dirt | |

| the trailing direction | in the counter direction | Downsizing | |

| Stabilization of | |||

| image density | |||

| along to main | |||

Dev. Unit | Two axis development New carrier adoption Dev roller

| Two axis one way development Dev roller

| direction High image quality High productivity More developer |

| amount | |||

| Prevent of toner | |||

| scattering |

Product Information

Toner supplement, Image transfer

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

Toner supply | HI-ACT system Sub hopper toner supply system Two types of toner near end (estimated near end and fixed near end) | Toner supply unit One type of toner near end | Less machine down time at toner bottle replacement |

| Waste toner bottle | Coil driven by intermediate image transfer unit motor | Coil driven by individual motor |

|

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

Image transfer | ITB cleaning unit position

No bias voltage on PTR Encoder less control (FG control) of ITB Adjustment value of ID sensor is provided by a seal attached on ID sensor | ITB cleaning unit position

| Downsizing

|

Process control | Real time process control

| Normal process control | Image quality stabilization and reduction of interval time |

Fusing

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

| Fusing sleeve material | |||

| change (Ni+Cu) | Fusing sleeve material | ||

| (SUS: stainless) | ||

| Fusing unit replacement | Three heaters | ||

| required only at | (one is postcard purpose) | AC-TEC | |

| SC544-02/554-02 | Fusing unit replacement | reduction | |

| occurrence | required at | Grease | |

| Fusing | Metal single purpose grease | SC544-00/554-00/564-00/ | lubulicant ability |

| adopted (Fluotribo) on | 574-00 occurrence | up | |

| pressure roller and the | Plastic purpose grease on | Machine layout | |

| bushing | pressure roller and the | change | |

| (this can be also used for the | bushing (Barrierta) | ||

| predecessors) | Pressure release motor turn | ||

| Pressure release motor turn | by both way | ||

| by one way |

Product Information

Electrical component

| Item | D146/D147/D148/D149/D150 | Predecessor | Purpose |

LCD | Two types of LCD (not compatible each other) | One type of LCD | Multi vender system |

IOB | Two IOB’s for image creation and paper transfer | One IOB | Optimized layout |

| NVRAM | Two EEPROM’s | One | |

| Flat Flexible Cable (FFC) | FFC used for main sigle line FFC with clip socket | Wire harness FFC without clip | Weight saving Handle ability improvement |

Main switch | DC SW Press and hold = forced OFF | Locker SW The plug must be pulled out for forced OFF. | (component change) |

FAX | Bracket added in the replacement FCU part | No bracket for FCU to hold | Handle ability improvement |

1.4.2 NEW FEATURES OF D146/D147/D148/D149/D150

| Item | Description |

Android operation panel | Android OS built in Simple UI for copy, scanner and FAX Advanced operational feeling |

| Searchable PDF (SD card option) | Scan function to add text information in the scan file |

| Image area extension option (paper transfer roller) | Wider paper transfer roller Real time process control deactivation is required. |

Log trace function | Enhancement for controller and engine log correction function |

1.4.3 IMPORTANT NOTICE FOR MACHINE

| Item | D146/D147/D148/D149/D150 | Predecessor |

| SP cord | SP enter code change | - |

Procedure at electrical board replacement | To hold the main switch down is always required before start procedure for electrical board replacement. (discharge of remaining charge) | No procedure |

VM function on CTL board | VM function built in CTL board. Accordingly, the procedure to update VM firmware is changed. | VM function is provided by SD card option. |

Grease used in fusing unit | Metal use purpose grease (Fluotribo) on pressure roller and bushing. | Traditional grease (Barrierta) |

Release way for Fusing high temperature detection | Fusing unit replacement is required only at SC544/554 (Fusing high temperature detection) occurrence. | Fusing unit replacement is required at SC544/554/564/574 occurrence. |

SRA3 option (Imageable Area Extension Unit Type M3) |

| - |

INSTALLATION

| RE V IS ION H IST ORY | ||

| Page | Date | Added/ Updated/ New |

| None |

INSTALLATION

INSTALLATION REQUIREMENTS

Installation

ENVIRONMENT

Temperature Range: 10°C to 32°C (50°F to 90°F) Humidity Range: 15% to 80% RH Ambient Illumination: Less than 1,500 lux (do not expose to direct sunlight.) Ventilation: Room air should turn over at least 30 m3/hr/person

- Avoid areas exposed to sudden temperature changes:

- Areas directly exposed to cool air from an air conditioner.

- Areas directly exposed to heat from a heater.

- Do not place the machine where it will be exposed to corrosive gases.

- Do not install the machine at any location over 2,000 m (6,500 ft.) above sea level. (D135 for NA can be installed only up to 2,500m (8,202 ft.))

- Place the main machine on a strong and level base. Inclination on any side should be no more than 5 mm (0.2").

- Do not place the machine where it may be subjected to strong vibrations.

- Avoid areas exposed to sudden temperature changes:

MACHINE LEVEL

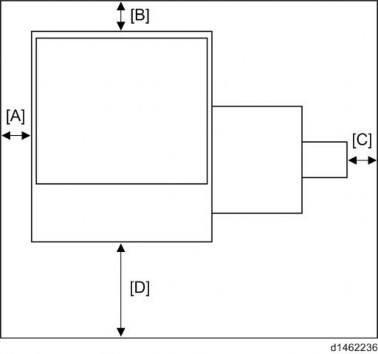

Front to back: Within 5 mm (0.2") Right to left: Within 5 mm (0.2")MACHINE SPACE REQUIREMENTS

[A] Left Over 100 mm (3.9")

[TD]Rear[/TD]

[TD]Over 100 mm (3.9")[/TD]

[TR]

[TD][C][/TD]

[TD]Right[/TD]

[TD]Over 100 mm (3.9")[/TD]

[/TR]

[TR]

[TD][D][/TD]

[TD]Front[/TD]

[TD]Over 750 mm (29.5")[/TD]

[/TR]

Put the machine near the power source with the clearance shown above.

Installation

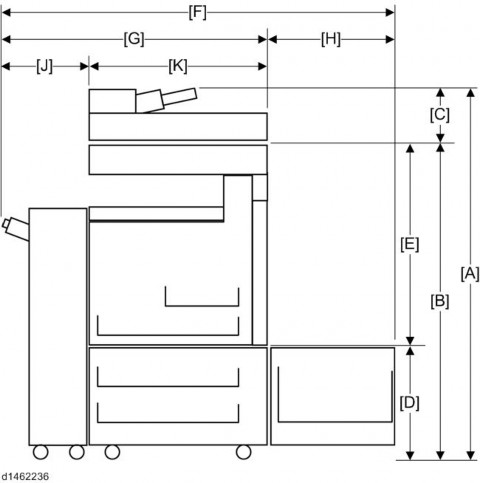

[*]MACHINE DIMENSIONS

[A] 1210 mm [F] 1589.5 mm

[TD]1030 mm[/TD]

[TD][G][/TD]

[TD]1249.5 mm[/TD]

[TR]

[TD][C][/TD]

[TD]180 mm[/TD]

[TD][H][/TD]

[TD]340 mm[/TD]

[/TR]

[TR]

[TD][D][/TD]

[TD]247 mm[/TD]

[TD][J][/TD]

[TD]662.5 mm[/TD]

[/TR]

[TR]

[TD][E][/TD]

[TD]783 mm[/TD]

[TD][K][/TD]

[TD]587 mm[/TD]

[/TR]

[*]POWER REQUIREMENTS

- Insert the plug firmly in the outlet.

- Do not use an outlet extension plug or cord.

- Ground the machine.

Input voltage level

Destination | Power supply voltage | Rated current consumption | Permissible voltage fluctuation |

NA | 120 to 127V | 12A or more | Imaging: 108V(120V-10%) to 138V(127V+8.66%) Motions: 102V(120V-15%) to 138V(127V+8.66%) |

| EU | 220 to 240V | 10A | Imaging: ±10% Motions: ±15% |

| AP | |||

| CHN |