HOME PAGE | < Previous | Contents | Next >

Replacement and Adjustment

Replacement and Adjustment

Replacement and Adjustment

4.13 FUSING UNIT

4.13.1 FUSING UNIT

Because there is a danger of burns on contact with hot parts of the fusing unit, start work when the temperature drops to a low enough temperature.

To clear SC544-02 or SC554-02, replacing the fusing unit or installing a fuse (provided in the fusing sleeve belt unit) in the fusing unit must be required. Refer to page 6-224 "When SC544-02, SC554-02 (Non-contact Thermistor High Temperature Detection) Is Displayed".

Fusing unit has a new unit detection mechanism, so it is not necessary to set SPs (New Unit Detection).

When the fusing unit is used past its target yield (400k), the fusing unit may break, causing a service call. Therefore, the machine displays a warning on the operation panel at 415k pages and stops at 430k pages.

1. Open the right door.

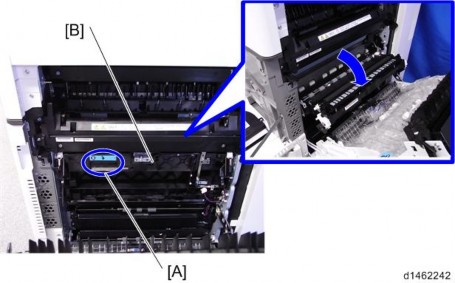

2. Pull the handle [A] and open the paper transfer unit [B].

3. Fusing unit [A]