HOME PAGE | < Previous | Contents | Next >

Internal Finisher SR3180 (D766)

Staple eject mechanism

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

Transport/adjustment of paper position (home position)

This finisher does not have a jogger. Paper position (side-to-side) is aligned using sensors, by registration adjustment during paper transportation.

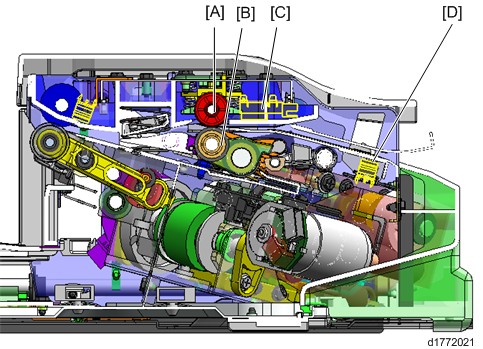

The leading edge of the paper transported from the main machine is detected by the entrance sensor [D]. After the trailing edge has passed through the paper exit rollers of the main machine, the paper is transported by the shift rollers ([A] and [B]) for shifting. The paper is shifted to the position where the side-to-side registration sensor [C] detects the rear edge of the paper (as viewed from the front of the machine). During paper shifting, the paper exit roller and paper exit belt move to the pressure release position.

Stacking (Position B)

Internal Finisher SR3180 (D766)

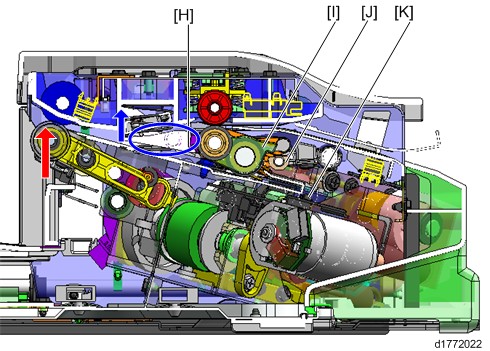

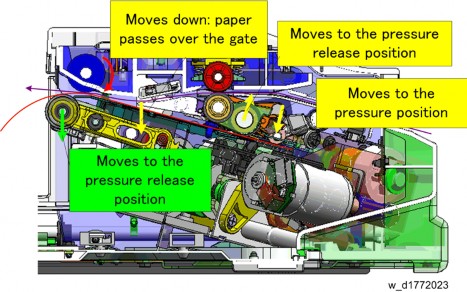

After shifting is completed, the paper exit rollers move to the strong pressure position and received the paper from the shift rollers. After the trailing edge of the paper has passed the junction gate, the paper exit roller rotates in the opposite direction. Paper is transported to the stacking area, and then passed through the reverse rollers [H].

At this time, the junction gate [J] moves to the lower position (the gate’s edge is raised, as shown by the blue arrow and circle) to bring paper to the stacking area.

After paper is transported to the reverse rollers, the paper exit rollers move to the pressure release position to allow shifting of the next sheets (as shown by the red arrow). When the transported sheet of paper touches the stack guide [K], the paper is aligned (main-scan direction). After the paper is stacked, the trailing edge presser [I] moves to the press position (the reverse rollers move to the pressure release position) and holds back the stacked paper.

Second sheet transport/adjustment (Position A)

Internal Finisher SR3180 (D766)

After the first sheet is stacked, the second sheet is shifted in the same way as the first sheet. During this time, the stacked paper is held back by the trailing edge presser.

Second sheet stacking

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

After the first sheet is shifted, the paper exit rollers and paper exit belt move to the weak pressure position, and transport the paper to the stacking area. The reverse rollers then receive the paper. The same is done to the third and subsequent sheets. The trailing edge presser holds back the stacked paper, and transports the second and subsequent sheets by sliding them onto the stacked paper.

Paper batch (Position C)

After the specified number of sheets are stacked, the batch of paper is stapled and transported through the paper exit rollers and paper exit belt. If the stapling method is set to “Double” using the user settings, the batch of paper is moved slightly and stapling is repeated.