HOME PAGE | < Previous | Contents | Next >

Internal Finisher SR3180 (D766)

Shift roller operation timing

Paper is shifted when the distance between the trailing edge and the paper exit roller on the main machine is 10mm (the entrance sensor detects the leading edge of the paper).

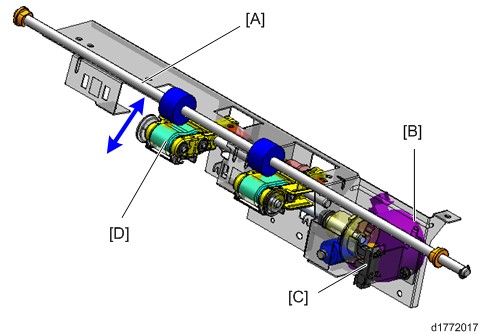

The shift motor [A] rotates clockwise/anti-clockwise to shift the paper towards the front/rear of the machine.

The shift amount is 20mm when shifting towards the front, and 10mm when shifting towards the back.

The home position is located at the back end of the shift area, and is detected by the shift roller HP sensor [B].

Paper exit roller/paper exit belt release mechanism

Pressure release timing of the paper exit rollers

Waiting (before paper is received): Strong pressure

When paper is transported: Pressure released

When paper shift is completed (shift motor stops): Strong pressure

When paper is transported, the paper exit rollers/paper exit belt ([A] and [D]) are at the pressure release position so that they do not interfere with paper shifting.

When paper shift is completed, the rollers are moved to the strong pressure position for paper transportation and paper exit.

Internal Finisher SR3180 (D766)

Positions of the paper exit roller/paper exit belt

HP (strong pressure)

Pressure release position

Weak pressure position

The paper exit pressure motor [B] rotates clockwise/anti-clockwise to drive the paper exit drive belt [D] to the strong pressure or weak pressure positions.

The paper exit pressure HP sensor [C] detects the home position.

Details of each position

Home position (strong pressure position)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

This is used for paper transportation and paper exit. The pressure increased using the motor [B], and the paper exit roller (drive) [A] and the paper exit belt (driven) [D] come into contact in order to nip the paper firmly.

[C] is the paper exit pressure HP sensor.

Pressure release position

The nip of the paper exit roller/paper exit belt is released so that they do not interfere with paper shift.

Internal Finisher SR3180 (D766)

Weak pressure position

This is used during stapling, when there is already paper stacked in the paper exit tray, and more paper is being transported.

The motor [A] lowers the pressure, and the position of the paper exit belt (driven) is moved so that the middle part of the belt comes in contact with the paper exit roller (drive).

The weak pressure position is for preventing smudges or stains caused by paper rubbing against the paper that is already stacked.