HOME PAGE | < Previous | Contents | Next >

Original Transport

At the beginning of the job, the original feed motor switches on and rotates the pick-up roller, feed belt, and reverse roller to feed the original into the original feed path.

The original is fed to the entrance roller as it leaves the original tray. Original skew is corrected at the entrance roller.

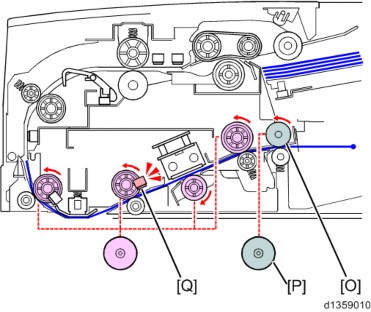

No. | Part |

A | Feed Motor |

B | Feed Belt |

C | Pick-up Roller |

D | ADF Separation Roller |

E | Entrance Roller |

F | Separation Sensor |

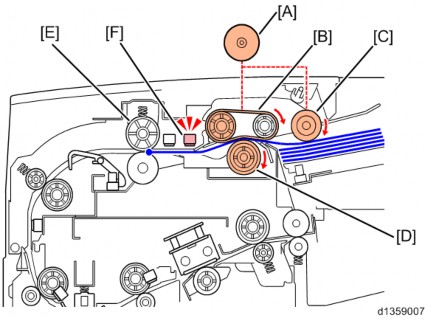

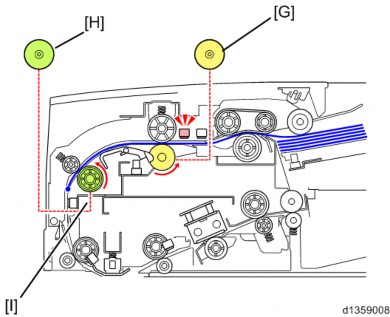

After skew is corrected at the entrance roller, the entrance motor [G] and transport motor [H] rotate the rollers in the original path and feed the original to the scanning section below.

SPDF DF3100 (D3B0)

SPDF DF3100 (D3B0)

SPDF DF3100 (D3B0)

SPDF DF3100 (D3B0)

No. | Part |

G | Entrance Motor |

H | Relay Motor |

I | Transport Roller |

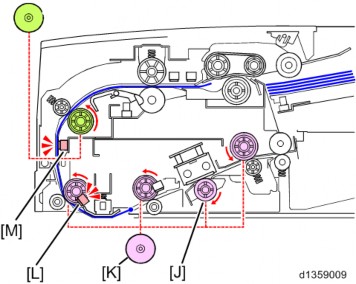

When the interval sensor [M] detects the original, the transport motor [K] turns on and rotates the white roller [J] and feeds the original through the scan unit.

After rotation of the entrance roller, the entrance motor speeds up slightly to reduce the gap between the trailing edge of the original in the scanning unit and the leading edge of the next original in the path.

If this were allowed to continue, the differences in roller rotation speed could cause the originals to bend or buckle in the original path around the pre-scanning roller.

To avoid this, when the interval sensor detects the leading edge of an original it slows the rotation of the scanning belt and the speed of the original in the nip of the pre-scanning roller slows.

SPDF DF3100 (D3B0)

When the original exit sensor [Q] detects the leading edge of the original, the exit motor [P] switches on and rotates the exit roller [O] which feeds the original out onto the original output tray.