Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

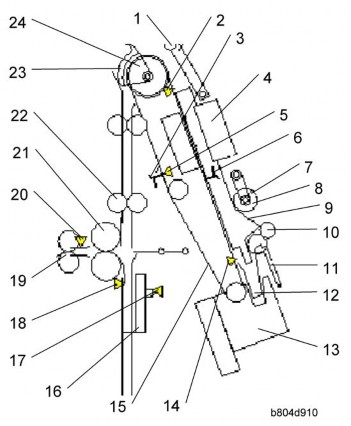

Stacker/Stapler - B804/B805

- Stack Present Sensor (S32)*1

- Stack Junction Gate HP Sensor (S27)*1

- Stack Feed Out Belt HP Sensor (S16)

- Feed Out Belt Motor (M5)

- Booklet Stapler EH185R – Rear (M23)*1

- Booklet Stapler EH185R – Front (M22)*1

- Jogger Fence Motor (M15)

- Jogger Fence HP Sensor (S15)

- Corner Stapler Movement Motor (M6)

- Stapling Tray Paper Sensor (S14)

- Corner Stapler EH530 (M20)

- Corner Stapler Rotation Motor (M13)

- Corner Stapler HP Sensor (S17)

- Stapler Rotation HP Sensor (S18)

- Stack Junction Gate Motor (M17) *1

*1: B804 Only

- Fold Cam HP Sensor (S30)

- Fold Bottom Fence HP Sensor (S28)

- Fold Unit Entrance Sensor (S26)

- Clamp Roller Retraction Motor (M8)

- Fold Unit Exit Sensor (S31)

B804 Fold unit

- Clamp Roller HP Sensor (S25)

- Fold Roller Motor (M12)

- Fold Plate Motor (M11)

- Fold Plate HP Sensor (S29)

- Fold Unit Bottom Fence Lift Motor (M16)

SUMMARY OF ELECTRICAL COMPONENTS

Here is a general summary of all the electrical components of the B804/B805 finishers.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

- In the table below a number that appears in bold text (M8, etc.) denotes a component that is on the 2000/3000 Sheet Finisher B804 only.

No. Component Function Boards (PCB) PCB1 Main Board The main board that controls the finisher PCB2 Booklet Stapler Board A separate board that controls booklet finishing. PCB3 Punch Unit Board The board that controls the punch unit. Motors

M1Finisher Entrance Motor Drives 1) the finisher entrance rollers, 2) and the punch waste transport belt of the punch unit.

M2

Upper Transport MotorDrives the paper feed rollers that feed paper 1) to the proof tray, 2) straight-through to the upper tray, 3) the pre-stack tray entrance roller.

M3

Lower Transport MotorDrives paper feed rollers forward and reverse in the pre-stack tray for the switchback, and drives the other rollers in the lower transport area.

M4

Upper/Proof Tray Exit MotorDrives 1) proof tray exit rollers, 2) extension and retraction of the stacking sponge roller, 3) upper tray exit rollers.

M5

Feed Out Belt MotorDrives the feed out belt that moves the stapled stacks out of the stapling tray after stapling.

M6

Corner Stapler Movement MotorMoves the corner stapler horizontally on a steel rod to position the stapler at the stapling position at 1) the front, 2) the rear (straight stapling), 3) the rear (diagonal stapling), or 4) the front and rear for double stapling.

No. Component Function

M7

Paper Position Sensor Slide MotorDrives the movement of the paper position slide that holds the paper position sensor (S3) that detects the position of the paper.

M8

Clamp Roller Retraction MotorDrives a large cam that alternately clamps and unclamps the clamp retraction roller, the idle roller of the clamp roller pair. When these rollers are clamped, they are part of the paper feed path and feed the stack toward the bottom fence of the fold unit. When the idle roller is retracted, the stacks falls a very short distance (3 mm) onto the fold unit bottom fence below. These rollers remain unclamped while the bottom fence positions the stack for folding and while the stack is folded by the fold rollers.

M9Punch Movement Motor Drives the front/back movement of the punch unit to position it correctly for stapling the paper below.

M10

Stacking Sponge Roller MotorRotates the stacking roller that drags each sheet back against the end fence to jog the bottom of each sheet after feed out to the upper tray.

M11

Fold Plate MotorDrives the fold plate that pushes the center of the stack into the nip of the fold rollers to start the fold.

M12

Fold Roller MotorRotates forward and drives the fold rollers that fold the stack and feed it out of the fold unit, reverses to feed the fold once more into the fold unit, and then rotates forward again to feed the fold out of the fold unit.

M13

Corner Stapler Rotation MotorSwivels the corner stapler and positions it so the staple fires at an oblique angle at the rear corner of the paper stack.

M14Positioning Roller Motor

Drives the positioning roller in the stapling tray.

M15

Jogger Fence MotorDrives the jogger fences in the stapling tray to jog both sides of the stack before stapling. Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)No. Component Function

M16

Fold Unit Bottom Fence Lift MotorRaises the bottom fence and stops when the center of the vertical stack is opposite the edge of the horizontal fold blade. The distance for raising the blade is prescribed as one-half the size of the paper selected for the job. For large paper, (A3, B4) the bottom fence first lowers the stack 10 mm below the fold position, and then raises it to the fold position.

M17

Stack Junction Gate MotorDrives the large cam that operates the stack junction gate at the top of the stapling tray. When this gate is open, it directs the ascending stack to the upper tray if it has been corner stapled, or if it is closed the gate turns the booklet stapled stack down so it falls onto the bottom fence of the folding unit.

M18

Shift Roller MotorDrives the shift roller that operates in shift mode to stagger document sets as they feed out to the upper tray (making them easier to separate).

M19

Exit Guide Plate MotorDrives the mechanism that raises and lowers the exit guide plate.

M20

Corner Stapler EH530This is the roving corner stapler, mounted on a steel rail that staples 1) at the front, 2) at the rear (straight staple), 3) at the rear (diagonal staple), and 4) font and rear (two staples).

M21

Upper Tray Lift MotorRaises and lowers the upper tray during feed out to keep the tray at the optimum height until it is full.

M22Booklet Stapler EH185R: Front Booklet stapler. Staples paper stacks in the center before they are folded.

M23Booklet Stapler EH185R: Rear Booklet stapler. Staples paper stacks in the center before they are folded. M24 Punch Drive Motor Fires the punches that punch the holes in the paper.

No. Component Function Sensors

S1

Finisher Entrance SensorProvides two functions: (1) Detects paper entering the finisher from the copier, and (2) Signals a jam if it detects paper at the entrance when the copier is switched on.

S2

Pre-stack Tray Exit SensorDetects 1) paper fed from the pre-stack tray to the stapling tray, and detects 2) paper in the pre-stack when the copier is switched on. (This sensor performs no timing function. The entire flow of paper through the

pre-stacking mechanism is controlled by motor pulse counts.)

S3

Paper Position SensorThe photosensor that detects the edge of the paper and sends this information to the punch unit board where it is used to position the punch for punching the holes in the paper.

S4

Punch Hopper Full Sensor1) A photosensor that detects and signals that the punch hopper is filled with punch waste and needs emptying, and 2) confirms the presence of the punch hopper and signals an error if it is missing or not installed completely.

S5

Shift Roller HP SensorLocated near the shift roller motor, controls the

front-to-back movement of the shift roller as shifts paper during straight-through feed.

S6

Upper Tray Exit SensorA flat, photo sensor located inside the guide plate, detects the leading edge and trailing edge of the paper as it feeds out to the upper tray during straight-through jobs (with and without stapling). When paper is fed to the upper tray, at the paper output slot this sensor signals an error when it detects (1) paper has failed to leave the paper exit (lag error), (2) detects paper has failed to arrive at the paper exit (late error), (3) detects paper is in the exit slot when the machine is turned on. Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)No. Component Function

S7

Exit Guide Plate HP SensorControls the vertical movement of the control exit

guide . The guide plate is in the home position when the guide plate is down and the actuator interrupts the sensor gap.

S8

Upper Tray Paper Height Sensor (Staple Mode)This is the upper sensor of the upper/lower paper height sensor pair that controls the lift of the upper tray. This sensor detects the paper height of the stack in the upper tray when the copier is operating in the staple mode.

S9

Upper Tray Paper Height Sensor (Non-Staple Mode)This is the lower sensor of the upper/lower paper height sensor pair that controls the lift of the upper tray. When the machine is switched on, the upper tray rises until the actuator on the tray triggers this sensor to switch off the upper tray lift motor.

S10

Proof Tray Exit SensorThis sensor detects and times the feeding of paper to the proof tray. It also detects whether paper is present at the proof tray exit when the copier is switched on.

S11

Proof Tray Full SensorThe top of the stack in the proof tray increases until it nudges the feeler of this sensor. The sensor then signals that the proof tray is full and the job halts until some paper is removed from the proof tray.

S12

Upper Tray Limit SensorThis sensor controls the position of the upper tray 1) during straight-through feed out, 2) during shift feed out,

3) when the machine is turned on. The machine obeys the signal of whichever sensor is actuated first.

An actuator attached to an arm triggers this sensor. The tip of the same arm depresses the upper tray limit switch If the sensor fails, the tip of the arm will activate the upper tray limit microswitch (SW2) and stop the lift of the upper tray.

Note: When the machine is turned on, the upper tray position is controlled by either this sensor or the upper tray paper height sensor (S9).

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)No. Component Function

S13

Stacking Roller HP SensorControls the forward and back motion of the stacking roller (a sponge roller) located at the output slot of the upper tray. The sponge roller drags each ejected sheet back against the end fence of the upper tray to keep the bottom of the stack aligned.

S14

Stapling Tray Paper SensorA photo sensor that detects whether paper is in the stapling tray. When this sensor detects paper, the bottom fence motor raises or lowers the bottom fence to position the selected paper size for booklet stapling.

S15

Jogger Fence HP SensorDetects the home position of the jogger fences. When the actuator on the jogger fence interrupts this sensor, the jogger fence is in its home position and the jogger fence motor (M15) stops.

S16

Stack Feed-Out Belt HP SensorControls the position of the stack feed-out pawl on the stack feed-out belt. Once the actuator on the feed belt nudges the feeler of this sensor near the top of the stapling unit, the feed out belt motor (M5) remains on for the time prescribed to position the pawl at the home position to catch the next stack.

S17

Corner Stapler HP SensorLocated at the front the stapling tray and mounted above the steel rod where the corner stapler travels, this sensor detects the home position of the corner stapler. The corner stapler is in its home position when the actuator on the corner stapler unit interrupts this sensor.

S18Stapler Rotation HP Sensor Controls the angle of the position of the corner stapler during oblique stapling.

No. Component Function

S19

Upper Tray Full Sensor (B804/B805)B804: When the actuator on the side of the upper fence enters the gap of this sensor, the sensor signals that the upper tray is at its lowest position (full) and stops the job.

B805: One of two upper tray full sensors. This is the higher tray full sensor for A3 and other heavy paper. The other upper tray full sensor (20) is for lighter paper.

S20

Upper Tray Full Sensor (B805 only)B804: This sensor is not used on the booklet finisher. There is only one upper tray full sensor (S18).

B805: One of two upper tray full sensors. This is the lower tray full sensor for A4 and smaller paper. The other upper tray full sensor (19) is for larger paper.

S21

Punch Unit HP SensorSwitches off the punch movement motor when the punch unit returns to its home position. Pulse counts determine where the punch unit pauses for punching and reversing.

S22

Paper Position Side HP SensorControls the movement of the paper position detection unit. Switches on when the horizontal detection unit is at the home position (HP is the reference point).

S23

Punch HP SensorDetects the home position of the punch unit and controls the vertical movement of the punches when they fire.

S24

Punch Encoder SensorWhen the punch mode is selected for the job (2-hole, 3-hole, etc.), the machine controls the operation of the punch drive (M24) motor which drives a small encoder shaped like a notched wheel. This wheel is rotated forward and reverse precisely to select which punches are moved up and down during the punch stroke.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)No. Component Function

S25Clamp Roller HP Sensor Controls the movement of the clamp retraction roller (the idle roller of the clamp roller pair).

S26

Fold Unit Entrance SensorDetects 1) the leading edge of the stack during booklet stapling, and 2) also used to signal an alarm if a paper is detected at the entrance of the fold unit when the copier is turned on.

S27

Stack Junction Gate HP SensorControls the opening and closing of the stack junction gate. Switches on when the stack junction gate is open and at the home position.

S28

Fold Bottom Fence HP SensorControls the movement of the bottom fence in the folding unit using pulse counts based on the size of the paper selected for the job to position the stack correctly for feeding.

S29

Fold Plate HP SensorAlong with the fold plate cam HP sensor (S30) this sensor controls the movement of the fold plate . The fold plate has arrived at the home position when the edge of the plate enters the gap of this sensor.

S30

Fold Plate Cam HP SensorAlong with the fold plate HP sensor (S29), this sensor controls the movement of the fold plate. The actuator mounted on the end of the roller that drives the folder plate forward and back makes three full rotations, i.e. the actuator passes the sensor gap twice and stops on the 3rd rotation and reverses. This accounts for the left and right movement of fold plate.

S31

Fold Unit Exit Sensor1) Detects the folded edge of the stack as it feeds out from the nip of the fold rollers, stops the rollers, and reverses them so the fold feeds back into the nip, 2) when the folded booklet finally emerges from the nip of the fold rollers, detects the leading and trailing edge of the booklet to make sure that it feeds out correctly.

No. Component Function

S32

Stack Present SensorThis sensor determines whether a there is paper at the turn junction gate when the machine is turned on. If a stack is present, this triggers a jam alert. (This sensor performs no dynamic function such as pulse counting, etc. It only detects whether paper is at the top of the folding unit when power its turned on.)

S33

Lower Tray Full Sensor - RearThis rear sensor is the lower sensor of the lower tray full sensor pair. Two actuators are attached to the actuator arm that touches the top of stapled and folded booklets as they feed out. The on/off combinations of the two sensors are used to detect when the tray is full and stop the job. (The lower tray is stationary. At tray full, the job halts until booklets are removed from the lower tray.)

S34

Lower Tray Full Sensor - FrontThis front sensor is the higher sensor of the lower tray full sensor pair. Two actuators are attached to the actuator arm that touches the top of stapled and folded booklets as they feed out. The on/off combinations of the two sensors are used to detect when the tray is full and stop the job. (The lower tray is stationary. At tray full, the job halts until booklets are removed from the lower tray.) Solenoids

SOL1

Proof Junction Gate SolenoidOpens and closes the proof tray junction gate. When the solenoid switches on, it opens the gate and paper is diverted to the proof tray. When this gate is closed, the paper goes straight to the upper tray. I

SOL2

Stapling Tray Junction Gate SolenoidDirects paper to the stapling tray. When this solenoid is on, paper feeds straight through. When this solenoid is off, paper feeds to the stapler tray below.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)No. Component Function

SOL3

Positioning Roller SolenoidEngages the stapler transport motor and the positioning roller of the stapling tray. The positioning roller pushes each sheet down against the bottom fence to align the bottom the stack for stapling. (The jogger fences align the sides.)

SOL4Stapling Edge Pressure Plate Solenoid Operates the pressure plate of the stapling unit. The pressure plate presses down the edge of stack in the stapling tray so it is tight for stapling.

SOL5

Booklet Pressure Roller SolenoidWhen the paper stack in the stapling tray feeds to the folding unit, this solenoid turns on and operates the roller that pushes on the surface of the stack to flatten it. Switches

SW1Front Door Safety Switch The safety switch that cuts the dc power when the front door is opened.

SW2

Upper Tray Limit SWA micro-switch that cuts the power to the upper tray lift motor when the upper tray reaches its upper limit. This switch duplicates the function of the upper tray limit sensor (S12) and stops the upper tray if S12 fails.

- In the table below a number that appears in bold text (M8, etc.) denotes a component that is on the 2000/3000 Sheet Finisher B804 only.

DRIVE LAYOUT

- Folder Plate Motor*1 (M11)

- Positioning Roller Motor (M14)

- Lower Transport Motor (M3)

- Entrance Motor (M1)

- Upper Transport Motor (M2)

- Upper/Proof Exit Motor (M4)

- Upper Tray Lift Motor (M21)

- Feed-Out Belt Motor (M5)

- Fold Roller Motor*1 (M12)

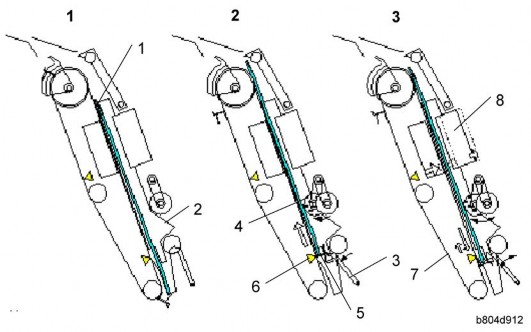

JUNCTION GATES

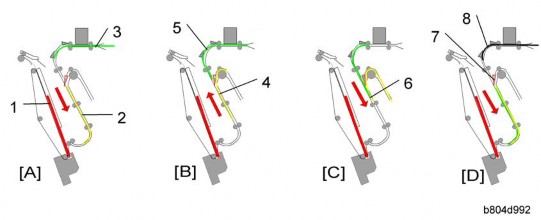

The positions of the proof tray and staple tray junction gates determine the direction of paper feed after paper enters the finisher.

PROOF MODE

Proof tray junction gate [A] opens. Staple tray junction gate remains closed. The proof tray junction gate directs paper to the proof tray above.

[*]SHIFT MODE

Proof tray junction gate [A] remains closed. Staple tray junction gate remains closed. With both junction gates closed, the paper goes to the upper tray.

[*]STAPLE MODE

Proof tray junction gate [A] remains closed. Staple tray junction gate opens

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

The staple tray junction gate directs the paper to the staple tray below for jogging and stapling.

[*]PRE-STACKING

This example describes what happens to Set 2 during the feed and stapling cycle of sets that contain three pages.

- [A]: While the Set 1 is being stapled in the staple tray [1], the 1st sheet of Set 2 [2] feeds to the pre-stack tray, and the 2nd sheet of Set 2 [3] enters the finisher.

- : The pre-stack junction gate opens and the 1st sheet of Set 2 [4] switches back to the top of the pre-stack tray as the 2nd sheet of Set 2 [5] starts to descend.

[*][C]: As the 2nd sheet of Set 2 continues to descend, the 1st sheet of Set 2 is fed from the pre-stack tray. At this time the leading edges [6] of both sheets are even.

[*][D]: The trailing edges of the 1st and 2nd sheets of Set 2 pass the junction gate [7] as the 3rd sheet of Set 2 [8] enters the finisher.

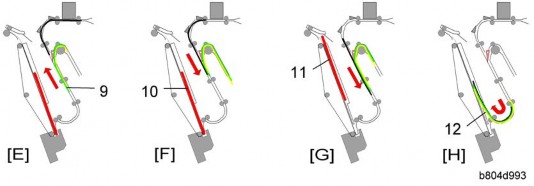

[*][E]: The 1st and 2nd sheets of Set 2 [9] switch back together into the top of the pre-stack and wait for the 3rd of Set 2 sheet to arrive.

[*][F]: The stapling of Set 1 in the staple tray [10] is completed.

[*][G]: Set 1 [11] exits the staple tray.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

[*][H]: The three sheets of Set 2 [12] feed together into the stapler tray for stapling. Pre-stacking is only done for A4, B5, and LT paper.

In one-staple mode, one sheet goes to the pre-stacking tray. Then two sheets go to the stapler tray at the same time.

In two-staple mode and booklet mode, three sheets go to the pre-stacking tray. Then four sheets go to the stapler tray at the same time.

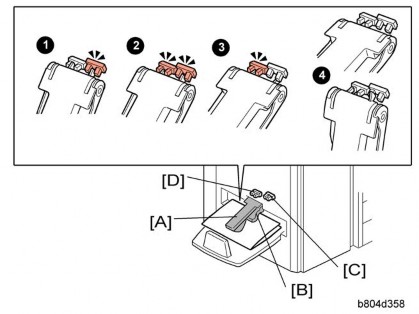

[*]TRAY MOVEMENT MECHANISM

UPPER TRAY

[A]: Upper Tray Lift Motor : Upper Feeler

[TD][E]: Lower Feeler[/TD]

[TR]

[TD][C]: Upper Tray Paper Height Sensor 1[/TD]

[TD][F]: Upper Tray Limit Sensor[/TD]

[/TR]

[TR]

[TD](Staple Mode)[/TD]

[TD][G]: Upper Tray Limit Switch[/TD]

[/TR]

[TR]

[TD][D]: Upper Tray Paper Height Sensor 2[/TD]

[TD][H]: Upper Tray Full Sensors[/TD]

[/TR]

[TR]

[TD](Non-Staple Mode)[/TD]

[TD][/TD]

[/TR]

- The B804 (shown above) has only one upper tray full sensor (the higher sensor at [H]).

- The B805 has two upper tray full sensors (the upper and lower sensor at [H]). On the B805 the upper sensor detects tray full for heavier paper (A3, DLT, B4, LG, 12 x 18”), and the lower sensor detects tray full for lighter paper (A4, LT, etc.).

- The tray full capacity is 2,000 sheets (B804) for A4, LT and 3,000 sheets (B805) for A4, LT.

Five sensors and one switch control the operation of the upper tray lift motor [A].

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Upper Tray Raising and Lowering

Operation ModeSensors, Switch Action [C] [D] [F] [G]

Standby (Non-Staple Mode)

OFF

OFFStops the lift motor is at the standby position when the actuator of the upper feeler deactivates sensor [C] (when it is between sensors [C] and [D]).

Note: Sensor [F] and switch [G] are used as backup if sensor [C] fails or if the upper tray is not attached.Straight Through ON Non-staple mode operation: During operation, tray lift is controlled only by sensor [F]. When the actuator leaves sensor [F], the tray lowers until the actuator reactivates sensor [F].

Shift

ON

Standby (Staple Mode)

ONStandby: The upper tray stops and waits for the paper output when the actuator activates sensor [C]. [D] is not used for staple mode

Staple Mode Operation:- The upper tray lowers the prescribed distance immediately after the stack exits.

- The upper tray rises until the actuator activates sensor [C] and stops the tray lift motor (and the tray) to wait for the next set.

- Sensor [F] and switch [G] are used as backup if sensor [C] fails.

Tray Full

B804When the actuator on the tray activates the upper tray full sensor [H] the tray lift motor [A] switches off. Operation resumes after some copies are removed from the tray. Upper Tray Capacity: 2,000 sheets (A4, LT)

B805The operation of the upper tray full sensor is the same as the B804. Capacity: 1,500 sheets for A3, B4 or other large paper.

An additional upper tray full sensor (below sensor [H]) allows more sheets to stack on the upper tray. Capacity: 3,000 sheets (A4, LT)

LOWER TRAY (B804 ONLY)

The lower tray sensor actuator arm [A] rests on the top of the stack of stapled booklets as they are output to the lower tray. A flap depressor keeps the open ends of the booklets down.

The front lower tray full sensor (S34) [C] and rear lower tray full sensor (S33) [D] detect when the lower tray is full of booklets.

- The front lower tray full sensor is mounted higher than the rear lower tray full sensor.

- The lower tray is stationary. When it becomes full, the stapling and folding job stops until booklets are removed from the tray.

- If the lower tray is not installed (this is detected if the front and rear sensors remain OFF), the machine will not operate in the booklet staple and fold mode. When booklet mode is selected, the tray full message appears on the operation panel.

The combinations of the two actuators and two sensors as the actuator arm rises determines the number of booklets that the lower tray can hold before the job stops.

The tray full detection depends on the size of the paper and the number of sheets in one stapled and folded booklet.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

In the table below, the conditions ( Ready Full 1, Full 2 Full 3: See the illustration on the previous page) refer to the states of the sensors described on the previous page.

Condition Front Sensor Rear Sensor Ready ON OFF Full 1 ON ON Full 2 OFF ON Full 3 (or lower tray not installed) OFF OFF

In the tables below:- "Sht" denotes "sheets in a stack".

- "Cnt" denotes "Count" (see below for an explanation).

After a booklet is feed out, the fold roller motor stops the exit roller. The machine then monitors the tray full sensors every 100 ms. The machine checks for a certain condition, based on the size of the paper and the number of sheets in the booklet.

An example is shown below. Tell the operators that the number of sheets that the lower tray can hold will vary greatly.

Lower Tray Full Condition Table A3 (DLT)

1 Sht 2 Sht 3 Sht 4 Sht 5 Sht 6 Sht 7 Sth 8 Sht 9 Sht … Full 1 3 Cnt — — — — — — — — …

Full 2

—

5 Cnt15

Cnt

—

—

—

—

—

—

…

Full 3

—

—

—

7 Cnt13

Cnt

4 Cnt

2 Cnt

2 Cnt

2 Cnt

…

A4 (LT)

1 Sht 2 Sht 3 Sht 4 Sht 5 Sht 6 Sht 7 Sth 8 Sht 9 Sht …

Full116

Cnt

—

—

—

—

—

—

—

—

…

Full 2

—10

Cnt10

Cnt15

Cnt20

Cnt15

Cnt10

Cnt

8 Cnt

8 Cnt

…Full 3 — — — …

Examples:

After the copier makes a booklet with 1 sheet of A3/DLT paper, the machine checks every 100 ms for the ‘Full 1’ condition. If the Full 1 condition occurs 3 times (shaded block in the table above), the machine detects that the tray is full.

After the copier makes a booklet with 5 sheets of A4/LT paper, the machine checks every 100 ms for the ‘Full 2’ condition. If the Full 2 condition occurs 20 times (shaded block in the table above), the machine detects that the tray is full.

[*]CORNER STAPLING

STACKING AND JOGGING

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

[A]: Jogger Fence Motor (M15) : Jogger Fences

[C]: Positioning Roller

[D]: Jogger Fence HP Sensor (S15)

[E]: Stapling Edge Pressure Plate Solenoid (SOL4) [F]: Pressure Plate

At the beginning of the job, the jogger fence motor (M15) [A] switches on and moves the jogger fences to the standby position (7.5 mm from the sides of the selected paper size).

When each sheet passes the pre-stack tray exit sensor (S2) and enters the stapling tray:

- The jogger fence motor switches on and moves the jogger fences to within 5.5 mm of the sides of the selected paper size.

- The positioning roller solenoid (SOL3) switches on for the time prescribed for the paper size. This pushes the positioning roller [C] onto the sheet and pushes it down onto bottom fence. This aligns the edge of the stack.

Next, the jogger fence motor: - Switches on again and moves the jogger fences to within 2.6 mm of the sides of the stack to align the sides of the stack.

- Reverses and moves the fences to the standby position (7.5 mm away for the sides) and waits for the next sheet.

- The jogger fence HP sensor [D] switches off the jogger motor at the end of the job. After the last sheet feeds:

- The stapling edge pressure plate solenoid [E] (SOL4) switches on and pushes the pressure plate [F] onto the stack to press down the edge for stapling.

- The corner stapler staples the stack.

STAPLER MOVEMENT

[A]: Stapler Movement Motor : Stapler

[C]: Stapler Rotation Motor

The stapler performs horizontal and rotational movement in each of the four staple modes:

- Front 1 staple

- Rear 1 staple

- Rear diagonal staple

- Rear/Front 2 staples

The stapler movement motor [A] drives a timing belt that moves stapler left and right on its stainless steel rail.

The stapler rotation motor [C] rotates the stapler into position for diagonal stapling at the rear.

[*]The stapler movement motor switches on and moves the stapler the standby stapling position. (This is the stapling position for the paper size selected for the job.)

[*]The stapler movement motor switches off and the stapler waits for the signal to fire (or swivel and for diagonal stapling).

If the stack is to be stapled at two positions:

[*]The stapler movement motor moves the stapler to the front position and staples the front.

[*]The stapler movement motor moves the stapler to the rear and the stapler staples the rear.

If the stack is stapled at the rear with a diagonal staple, the staple moves to the rear. When it is time for stapling, the rotation motor rotates the stapler to the correct angle and holds the stapler in that position while the stapler fires.

The stapling positions can be fine adjusted with SP6-133-001.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

[*]CORNER STAPLING

Staple firing is driven by the stapler motor [A] inside the stapler unit. The stapler hammer fires the stapler [C].

The cartridge set sensor [D] detects the cartridge at the correct position. The staple end sensor [E] detects the staple end condition.

[*]BOOKLET STAPLING (B804 ONLY)

BOOKLET PRESSURE MECHANISM

[A]: Booklet Pressure Roller Solenoid (SOL5) : Booklet Pressure Roller Arm

[C]: Booklet Pressure Roller

As soon as the edges are aligned by the positioning roller and the jogger fences, the stack feed out belt moves.

In booklet mode, immediately after the edges are aligned by the positioning roller and jogger fences, the booklet pressure solenoid switches on and the booklet pressure roller presses down on the stack until booklet stapling is finished. This prevents the stack from shifting during stapling.

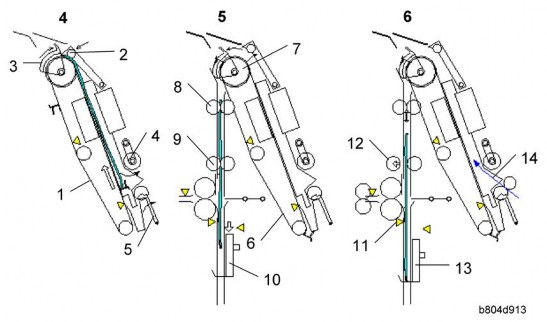

[*]BOOKLET STAPLING AND FOLDING

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

- Leading Edge Pressure Roller

- Stack Present Sensor (S32)

- Feed Out Belt Pawl 1

- Booklet Staplers x2 (M22, M23)

- Stack Feed Out Belt HP Sensor (S16)

- Feed Out Belt Pawl 2

- Positioning Roller

- Booklet Pressure Roller (Rear)

- Jogger Fences x2

- Pre-Stack Exit Roller

- Pressure Plate

- Stapling Tray Bottom Fence

- Corner Stapler (M20)

- Stapling Tray Paper Sensor (S14)

- Feed Out Belt

- Fold Unit Bottom Fence

- Fold Bottom Fence HP Sensor (S28)

- Fold Unit Entrance Sensor (S26)

- Fold Unit Exit Rollers x2

- Fold Unit Exit Sensor (S31)

- Fold Rollers x2

- Clamp Rollers x2

- Stack Junction Gate

- Stack Transport Roller

1:

The last sheet of the stack [1] enters the stapling tray. The jogger fences [2] jog the last sheet into position (based on the width of the selected paper size) and then retract and stop 1 mm away from the sides of the stack.

2:

The pressure plate [3] and booklet pressure roller [4] press down on the sheet. The stack feed out belt switches on and the pawl [5] on the feed out belt catches the bottom of the stack and raises it. The stapling tray sensor [6] detects the trailing edge of the paper stack.

3:

The feed out belt [7] raises the stack to the prescribed stapling position and stops. The jogger fences move to the sides of the stack and the booklet staplers [8] staple the stack.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

4:

The jogger fences remain 1 mm away from the sides of the stack. The feed out belt [1] raises the stack until the top of the stack is 10 mm past the leading edge pressure roller [2] and stops. The leading edge pressure roller descends and applies pressure to the top of the stack. The stack junction gate [3] (normally open) closes. The pressure roller [4] and pressure plate [5] retract.

5:

The feed out belt [6], transport rollers [7], [8], and clamp rollers [9] rotate and feed the stack past the closed stack junction, over the top and down toward the bottom fence [10]. At the same time, the fold unit bottom fence descends from its home position and stops 10 mm below the fold position.

6:

The rollers feed the leading edge of the stack to within 3 mm of the stack stopper of the bottom fence [13]. The fold unit entrance sensor [11] detects the stack and opens the clamp rollers [12]. The stack drops 3 mm onto the fold unit bottom fence [13]. At this time, the first sheet [14] of the next stack feeds to the stapling tray.

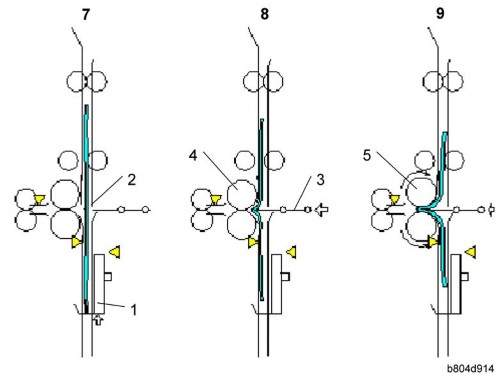

7:

The bottom fence [1] raises the stack to the prescribed fold position [2].

8:

The fold plate [3] moves to the left and advances 1/3 its maximum horizontal stroke and exerts 20 kg (44 lb.) of pressure at the fold rollers [4].

9:

With the fold plate pushing the stack into nip of the fold rollers [5], the fold rollers begin to rotate and fold the stack as it feeds out.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

10:

When the fold rollers [1] feed the stack 10 mm past the nip, the fold plate retracts until it no longer touches the stack. The fold unit exit sensor [2] detects the folded edge of the stack and stops the fold rollers.

11:

The rotation of the fold rollers [4] reverses and feeds the folded edge back until only 3 mm of the fold [5] remains at the nip.

12:

The fold rollers [6] rotate forward once again feed out. The fold unit exit sensor [7] once again detects the edge of the fold.

- You can do SP6-136-001 to increase the sharpness of the fold. The number of forward and reverse feeds can be set in the range of 2 to 30. The machine repeats Steps 11 and

12. For more, please refer to Section "Service Tables".

13:

With the feed of the stack halted, the fold plate [1] retracts. The fold plate HP sensor (not shown) detects the fold plate and stops it at its home position.

14:

The fold rollers [2] and fold unit exit rollers [3] begin to rotate together and feed out the folded booklet to the lower tray.

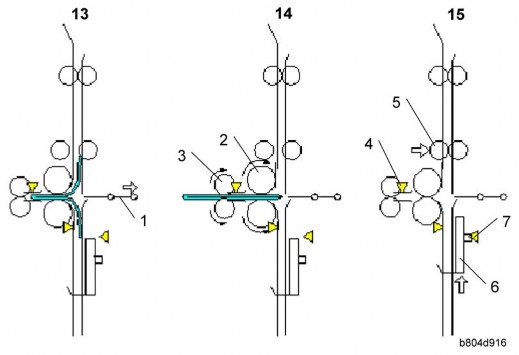

15:

Once the trailing edge of the stack passes the fold unit exit sensor [4], the clamp rollers [5] close to be ready to feed the next stack. The fold unit bottom fence [6] descends. The bottom fence HP sensor [7] stops the bottom fence when it detects the actuator on the bottom fence.

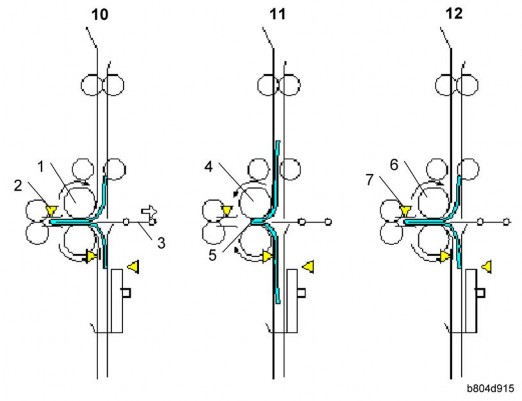

BOOKLET STAPLING AND FOLDING MECHANISMS

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Booklet Stapler

[A]: Feed Out Belt Pawl. Raises the stack to stapling position. : Booklet Stapler EH185R – Rear

[C]: Booklet Stapler EH185R – Front

Stack Junction Gate

[D]: Stack Junction Gate Motor. Drives a timing belt and stack junction gate cam. [E]: Stack Junction Gate Cam. Opens and closes the stack junction gate.

[F]: Stack Junction Gate. The stack junction gate motor and stack junction gate cam close the stack junction gate. The feed out belt pawl raises the stapled stack and sends it over the top and down to the fold unit.

[G]: Leading Edge Pressure Roller. Presses down on the leading edge of the stack after booklet stapling.

Clamp Roller

[A]: Fold Roller Motor. Drives the stationary clamp drive roller as well as the fold rollers (see next page).

: Clamp Rollers.

Clamp Roller – Drive. Rotated by the fold roller motor, this stationary roller feeds the stack down with the retracting roller closed.

Clamp Roller – Retracting. Opened and closed by the retraction motor [C].

[C]: Clamp Roller Retraction Motor. Operates the clamp roller cam that retracts the retracting clamp roller. The clamp rollers feed the stack to within 3 mm of the bottom fence when closed and then open to drop the stack onto the bottom fence.

[D]: Clamp Roller HP Sensor. Controls the rotation of the clamp roller retraction motor and cam that open and close the retracting clamp roller.

[E]: Clamp Roller Cam. Forces open the spring loaded retracting clamp roller.

Bottom Fence

[F]: Bottom Fence. Raises the booklet stapled stack to the fold position.

[G]: Bottom Fence HP Sensor. Detects the actuator on the bottom fence and stops it at the home position after folding.

[H]: Bottom Fence Lift Motor. Raises the bottom fence and stapled stack to the fold position prescribed for the paper size.

Fold Plate

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

[A]: Bottom Fence Stack Stoppers. Catches the stack after it is released by the clamp rollers. : Fold Plate Motor. Drives the timing belt and gears that move the fold plate.

[C]: Fold Plate Cam. Controls the movement of the fold plate to the left (into the nip of the fold rollers) and right (toward the fold plate home position).

[D]: Fold Plate HP Sensor. Controls operation of the fold plate motor.

[E]: Fold Plate. Moves left and pushes the stack into the nip of the fold rollers and then moves right to retract.

Fold Rollers

[F]: Fold Roller Motor. Drives forward to feed out the stack at the fold and then reverses to feed the fold in to sharpen the crease, and then drives forward again to feed out the folded stack. This reverse/forward cycle is done once.

- This cycle can be repeated by changing the setting of SP6114.

[G]: Fold Rollers. Driven by the fold roller motor, this roller pair feeds out the stack at its fold, reverses to feed in the stack to, and then feeds forward again (assisted by the fold unit exit rollers

– not shown) to feed out the stack to the lower tray.

[*]UPPER TRAY OUTPUT

FEED OUT

[A]: Feed Out Belt Motor : Stack Feed-Out Belt [C]: Pawl

[D]: Exit Rollers

[E]: Exit Guide Plate Motor [F]: Exit Guide Plate

[G]: Exit Guide Plate HP Sensor [H]: Upper Tray

After the stack is stapled, the feed out belt motor [A] switches on and drives the feed out belt . The pawl [C] attached to the feed out belt catches on the stack and lifts the stack toward the feed out slot.

The exit guide plate [F] remains open as the stack emerges at a prescribed distance away from the exit roller.

Next, the exit guide plate closes and the exit roller feeds the stack out.

The opening and closing of the exit guide plate is controlled by the rising and falling of a link driven by a rotating cam attached to the shaft of the exit guide plate motor [E].

The feed out belt motor stops 300 ms to prevent the stapled stack from rising too high.

Next, the feed out belt motor switches on again, then the pawl actuates its home position sensor and switches off the motor.

There are two output pawls on the feed out belt to improve the productivity of the feed out operation.

[*]FEED OUT STACKING

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Upper/proof exit motor [A] drives feed roller and stacking sponge roller [C].

Stacking sponge roller motor [D] moves the sponge roller forward and back with link [E].

The position of the stacking sponge roller [C] is controlled by the stacking sponge roller motor which is switched on and off by the stacking roller HP sensor [F].

[*]PUNCH UNIT B702 (FOR B804/B805)

OVERVIEW OF OPERATION

Skew Correction before Punching

This punch unit corrects for paper skew and then positions the punch unit to punch holes at the correct position. Each sheet is punched one at a time.

Paper feeds out of the copier. The finisher entrance sensor [A] detects the leading edge of the sheet.

The finisher entrance roller stops rotating briefly while the copier exit rollers continue to rotate. This buckles the paper against the finisher entrance roller to correct skew. The finisher entrance roller [C] starts to rotate again and feeds the sheet into the finisher.

These SP codes adjust the skew operation in the punch unit:

- SP6130. This SP corrects the punch hole alignment. To do this, it corrects the skew of each sheet by adjusting the amount of time the finisher entrance roller remains off while the exit roller of the machine remains on. For more, see Section "Service Tables".

- SP6131. This SP determines whether the finisher entrance roller stops to correct skew when paper enters the finisher. You can use this SP to disable the skew correction. For more, see Section "Service Tables".

Punch Unit Position Correction

These operations (skew correction before punching, and punch unit position correction) increase the accuracy of the punch alignment.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

:

The trailing edge of the sheet passes the finisher entrance sensor [A].

The paper position slide unit moves the paper position sensor [C] forward to the edge of the paper.

The paper position sensor detects the position of the paper edge and sends this information to the punch unit board. The machine uses the detected position of the paper edge to calculate the correct position for punching.

The upper transport motor switches on and rotates the feed rollers [D] the prescribed distance to position the paper under the punch unit.

:

Using the result of the position calculation, the punch unit control board moves the punch unit [E] to the adjusted punch position.

The paper position slide unit and its paper sensor, move back to the paper position slide home position sensor [F], and the punch unit fires the punches to make the holes.

:

The feed rollers [G] feed the punched paper out of the punch unit and into the paper path.

These SP codes adjust the punch hole alignment:

[*]SP6-128 Adjusts the punch positions in the direction of paper feed.

[*]SP6-129 Adjusts the punch position perpendicular to the direction of feed. For more, see Section "Service Tables".

[*]PUNCH MECHANISMS

Paper Position Detection

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

[A]: Finisher Entrance Motor (M1) : Finisher Entrance Roller

[C]: Finisher Entrance Sensor (S1)

[D]: Paper Position Sensor Slide Motor (M7) [E]: Paper Position Sensor (S27)

[F]: Paper Position Sensor Slide HP Sensor (S22)

The finisher entrance motor (M1) [A] drives the finisher entrance rollers that feed paper from the copier into the finisher. The finisher entrance sensor (S1) [C] detects paper when it enters the finisher, and detects paper jams.

The paper position slide sensor motor (M7) [D] extends and retracts the paper position slide that holds the paper position sensor (S27) [E]. The paper position sensor detects the position of the paper edge. The detected position of the paper is used to calculate and position the punch unit for punching.

The paper position slide HP sensor (S22) [F] detects the paper position slide when it retracts and stops the paper position slide motor so the slide stops at its home position.

Punch Unit Movement

[A]: Punch Movement Motor (M9)

: Punch Movement HP Sensor (S21) [C]: Punch Drive Motor (M24)

The punch movement motor (M9) [A] extends and retracts the punch unit to position it at the correct position for punching.

The punch movement HP sensor (S21) detects the position when it retracts, switches off the punch position movement motor, and stops the punch unit at its home position.

The punch drive motor (M24) [C] fires the punches that punch holes in the paper below.

Punch Selection and Firing

[A]: Punch Drive Motor (M24) : Punch Encoder Wheel

[C]: Punch Encoder Sensor (S24) [D]: Punch HP Sensor (S23)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

The punch drive motor (M24) [A] turns the small, notched encoder wheel through the gap in the punch encoder sensor [C] (S24). The sensor output is used to control the punch timing.

The timing for 2-hole punching [E] is different from 3-hole punching [F].

When the punch unit is at the punching position, the punch motor turns until the encoder detects the starting position for 2-hole or 3-hole punching.

- This is the ‘1’ position in the diagrams (the top diagram is for 2-hole punching, and the bottom diagram is for 3-hole punching).

Then, the punch drive motor turns counter-clockwise to the ‘2’ position. This movement punches the holes in the paper.

Then, the punch drive motor turns clockwise to the ‘1’ position, to be ready for the next sheet of paper.

PUNCH HOPPER MECHANISM

[A]: Finisher Entrance Motor (M1) : Punch Waste Belt

[C]: Punch Waste Hopper

[D]: Punch Hopper Full Sensor (S4)

The finisher entrance motor (M1) [A] drives the timing belt and gears that rotate the punch waste belt .

The punchouts fall from the punch unit onto the belt. The belt moves the punchouts to the front and dumps them in the punch waste hopper [C].

The punch hopper full sensor [D]:

- Signals that the hopper is full when it detects the top of the stack of punchouts that have collected in the hopper.

- It also detects when the punch hopper is set properly.

[*]FINISHER JAM DETECTION

| Display | Mode | Jam | What It Means |

R1 to R3 | Proof Shift Staple | Finisher entrance sensor late | After main machine exit sensor goes OFF, finisher entrance sensor does not go ON even after enough time to feed 450 mm. |

| Finisher entrance sensor lag | After finisher entrance sensor goes ON, it does not go OFF after enough time to feed a sheet 1.5 times its length has elapsed. | ||

R3 | Proof | Proof exit sensor late | After finisher entrance sensor goes ON, proof exit sensor does not go ON even after enough time to feed 450 mm. |

Proof exit sensor lag | After finisher entrance sensor goes OFF, proof exit sensor does not go OFF even after enough time to feed 450 mm. |

| Display | Mode | Jam | What It Means |

R4 | Shift | Upper tray exit sensor late | After finisher entrance sensor goes ON, upper tray exit sensor does not go ON even after enough time to feed 485 mm. |

Upper tray exit sensor lag | After finisher entrance sensor goes OFF, upper tray exit sensor does not go OFF even after enough time to feed 650 mm. | ||

R5 to R7 | Staple | Pre-stack tray exit sensor lag | After finisher entrance sensor goes ON, pre-stack tray exit sensor does not go ON even after enough time to feed 650 mm. |

Pre-stack tray exit sensor late | After finisher entrance sensor goes ON, pre-stack tray exit sensor does not go OFF even after enough time to feed 1650 mm. | ||

R8 to R12 | Booklet Staple (B700 Only) | Fold unit entrance sensor late (S26) | The fold unit entrance sensor goes not go ON after enough time has elapsed to feed 1.5 times the length of the stack after the leading edge of the stack reaches the stack present sensor (S32). |

| Fold unit exit sensor late (S31) | The fold unit exit sensor does not go ON after enough time has elapsed for the stack to feed 1.5 times its length from the fold position. | ||

| Fold unit exit sensor lag (S31) | After the fold unit exit sensor goes ON, it does not go OFF after enough time has elapsed to feed 442.9 mm. |

| R EVI SIO N HIS TORY | ||

| Page | Date | Added/ Updated/ New |

| None |

D641 PRINTER/SCANNER UNIT TYPE 5002

PRINTER/SCANNER UNIT TYPE 5002 (D641)

TABLE OF CONTENTS

INSTALLATION 1

- OVERVIEW 1

- PRINTER/SCANNER OPTIONS 1

- OTHER OPTIONS 2

- BOARD, SD CARD SLOTS 3

Board Slot 5

SD Card Slot 6

USB Slots 6

- PRINTER AND P/S OPTIONS (BASIC MODELS) 7

- OVERVIEW 7

Three Main Units 7

Separate Options 8

Enhance Options 8 - KIT CONTENTS 8

Common Accessory Table 8 - PRINTER/SCANNER INSTALLATION 9

- SCANNER ENHANCE OPTION 12

Accessory Check 12

Installation (Application Merge) 12

To undo an option update 13

Important Notes about SD Cards 13 - APPLICATION MERGE 14

If more than one application is required… 14

- OVERVIEW 7

- INSTALLING CONTROLLER OPTIONS 15

- OVERVIEW 15

Board Slot 15

SD Card Slots 15

USB Slots 15 - POSTSCRIPT 3 UNIT (D641) 16

- FILE FORMAT CONVERTER (D377) 17

- IEEE 1284 INTERFACE BOARD (B679) 18

SM i D641

1.3.5 IEEE 802.11A/G OR G (D377) 19

User Tool Settings for IEEE 802.11a/g 20

SP Mode Settings for IEEE 802.11 Wireless LAN 22

- BLUETOOTH UNIT (D566) 23

- GIGABIT ETHERNET (G874) 24

- IPDS UNIT (D641) 25

Accessories 25

Installation 26 - VM CARD TYPE U (D640) 28

Accessories 28

Installation 29

- CHECK ALL CONNECTIONS 30

- OVERVIEW 15

- OVERVIEW 1

SERVICE TABLES 31

- PRINTER SERVICE TABLES 31

- SP1-XXX (SERVICE MODE) 31

- SCANNER SERVICE TABLES 41

- SP1-XXX (SYSTEM AND OTHERS) 41

- SP2-XXX (SCANNING-IMAGE QUALITY) 43

- PRINTER SERVICE TABLES 31

SPECIFICATIONS 44

- PRINTER SPECIFICATIONS 44

- USB SPECIFICATIONS 46

- IEEE 802.11A/B/G SPECIFICATIONS 46

- BLUETOOTH SPECIFICATIONS 47

- SCANNER SPECIFICATIONS 47

- SOFTWARE ACCESSORIES 48

- PRINTER DRIVERS 48

- SCANNER AND LAN FAX DRIVERS 48

- UTILITY SOFTWARE 49

D641 ii SM

Last edited: