6140 | Bit | Description | Reading |

| 0 | 1 | ||

042 | Booklet Stapler 1: Staple In (Leading Edge/Front) | No staple detected | Staple detected |

043 | Booklet Stapler 1: Operation (Rotation/Rear) | Not HP | HP |

| 044 | Booklet Stapler 1: Staple In (Rear) | No staple detected | Staple detected |

045 | Booklet Stapler 1: Staple In (Leading Edge/Rear) | No staple detected | Staple detected |

| 046 | Upper Tray Full Sensor: 3000 | Not Full | Full |

*1: Combination of DIP SW 1 and SW 2

| DIP SW 1 | DIP SW 2 | Punch Type |

| 0 | 0 | Japan |

| 1 | 0 | Europe |

| 0 | 1 | North America |

| 1 | 1 | North Europe |

*2: Please refer to "Lower Tray (D637 Only)" in the Service Manual for the "3000/2000-Sheet (Booklet) Finisher ".

Service Tables

1000-Sheet Finisher (D588)

6139 | Bit | Description | Reading |

| 0 | 1 | ||

001 | Entrance Sensor | Paper detected | No paper detected |

002 | Shift Exit Sensor (Lower Tray Exit Sensor) | No paper detected | Paper detected |

003 | Staple Entrance Sensor (Stapler Tray Entrance Sensor) | Paper detected | No paper detected |

004 | Staple Moving HP Sensor (Stapler HP Sensor) | Not HP | HP |

005 | Jogger HP Sensor (Jogger Fence HP Sensor) | Not HP | HP |

| 006 | Stack Feed-out Belt HP Sensor | HP | Not HP |

| 007 | Staple Tray Paper Sensor | No paper detected | Paper detected |

008 | Staple Rotation Sensor (Staple Rotation HP Sensor) | Not HP | HP |

009 | Staple Sensor | Staple detected | No staple detected |

010 | Staple READY Detection | Staple detected | No staple detected |

011 | Exit Guide Plate HP (Exit Guide Plate HP Sensor) | Not HP | HP |

| 012 | Shift HP Sensor | Not HP | HP |

013 | Paper Sensor (Stack Height Sensor) | No output tray detected | Output tray detected |

014 | Tray Lower Sensor (Lower Tray Lower Limit Sensor) | Lower limit | Not lower limit |

6139 | Bit | Description | Reading |

| 0 | 1 | ||

015 | Proof Full Sensor (Paper Limit Sensor) | Not full | Full |

OUTPUT CHECK TABLE

Copier

5804 Output Check 001 Exit Motor: 350

Paper exit motor (Mainframe)002 Exit Motor: 175 003 Exit Motor: 230 004 Exit Motor: 180 005 Exit Motor: 154 006 Exit Motor: 90 007 Feed Motor: 300

Paper feed motor (Mainframe)008 Feed Motor: 255 009 Feed Motor: 230 010 Feed Motor: 215 011 Feed Motor: 180 012 Feed Motor: 154 013 Feed Motor: 90 014 Bank: Feed Motor: 300

Paper feed motor (Optional paper feed unit)015 Bank: Feed Motor: 255 016 Bank: Feed Motor: 230 Service Tables5804 Output Check 017 Bank: Feed Motor: 215 018 Bank: Feed Motor: 180 019 Bank: Feed Motor: 154 020 Bank: Feed Motor: 90 021 LCT: Feed Motor: 300

Paper feed motor (Optional LCT)022 LCT: Feed Motor: 255 023 LCT: Feed Motor: 230 024 LCT: Feed Motor: 215 025 LCT: Feed Motor: 180 026 LCT: Feed Motor: 154 027 LCT: Feed Motor: 90 028 Paper Feed Clutch 1

Paper feed clutch 1/2 (Mainframe)029 Paper Feed Clutch 2 030 Bank: Paper Feed Clutch 3

Paper feed clutch 3/4 (Optional paper feed unit)031 Bank: Paper Feed Clutch 4 032 LCT: Paper Feed Clutch Paper feed clutch (Optional LCT) 033 Pick-up Solenoid 1

Pick-up Solenoid 1/2 (Mainframe)034 Pick-up Solenoid 2 035 Bank: Pick-up Solenoid 3

Pick-up Solenoid 3/4 (Optional paper feed unit)036 Bank: Pick-up Solenoid 4 037 LCT: Pick-up Solenoid Pick-up Solenoid (LCT) 038 Tray Lift Motor 1: Up

-039 Tray Lift Motor 1: Down 040 Tray Lift Motor 2: Up

5804 Output Check 041 Tray Lift Motor 2: Down 042 Paper Tray Lock Solenoid Not used

043

Bank: Paper Tray Lock SolenoidTray lock solenoid (Optional paper feed unit) 044 Registration Motor: 230

-045 Registration Motor: 180 046 Registration Motor: 154 047 Registration Motor: 90 048 Exit: Junction Gate Solenoid Junction gate 1 solenoid 049 Duplex: Inverter Gate Solenoid Not used 050 Duplex Inverter Motor: Fwd: 230

-051 Duplex Inverter Motor: Fwd: 180 052 Duplex Inverter Motor: Fwd: 154 053 Duplex Inverter Motor: Fwd: 90 054 Duplex Inverter Motor: Rev: 230 055 Duplex Inverter Motor: Rev: 180 056 Duplex Inverter Motor: Rev: 154 057 Duplex Inverter Motor: Rev: 90 058 Duplex/By-pass Motor: Fwd: 230

-059 Duplex/By-pass Motor: Fwd: 180 060 Duplex/By-pass Motor: Fwd: 154 061 Duplex/By-pass Motor: Fwd: 90 062 Duplex/By-pass Motor: Rev: 230 063 Duplex/By-pass Motor: Rev: 180 Service Tables5804 Output Check 064 Duplex/By-pass Motor: Rev: 154 065 Duplex/By-pass Motor: Rev: 90 066 By-pass Feed Clutch - 067 By-pass Pick-up Solenoid - 068 Bridge/Exit Tray: Drive Motor: 230

Drive motor (Bridge unit)069 Bridge/Exit Tray: Drive Motor: 180 070 Bridge/Exit Tray: Drive Motor: 154 071 Bridge/Exit Tray: Drive Motor: 90

072Bridge/Exit Tray: Junction Gate Solenoid Junction Gate Solenoid (Bridge unit) 073 Bridge/Exit Tray: Drive Motor: Reset - 074 Bridge/Exit Tray: Drive Motor: Enable - 075 Bridge: Cooling Fan Motor Not used 076 Transfer Belt Contact Motor - 077 OPC Motor: 230

Drum motor078 OPC Motor: 180 079 OPC Motor: 154 080 OPC Motor: 90 081 Transfer/Development Motor: 230

-082 Transfer/Development Motor: 180 083 Transfer/Development Motor: 154 084 Transfer/Development Motor: 90 085 Fusing Motor: 230

-086 Fusing Motor: 180

5804 Output Check 087 Fusing Motor: 154 088 Fusing Motor: 90 089 Development Paddle Motor - 090 PTL Control - 091 Fusing Fan Motor: High

Fusing exhaust fan motor092 Fusing Fan Motor: Low 093 Exhaust Fan Motor: High

Exhaust fan motor094 Exhaust Fan Motor: Low 095 Duct Fan Motor Cooling fan motor 096 Exit Fan Motor: High

Paper exit cooling fan motor097 Exit Fan Motor: Low 098 PSU Fan Motor -

099

1-Bin Junction Gate SolenoidJunction gate 2 solenoid (1-bin unit) 100 Polygon Motor: 230

-101 Polygon Motor: 180 102 Polygon Motor: 154 103 Polygon Motor: 90 104 LD 1

-105 LD 2 106 Toner Bottle Motor: Fwd Toner supply motor 107 Quenching Lamp - 108 Charge Bias - 109 Development Bias - 5804 Output Check 110 Transfer Belt Voltage - 111 ID Sensor LED - 115 Cleaning Web Motor Web motor 116 Shift Tray Motor Not used 117 CTL Cooling FAN Controller fan 202 Scanner Lamp -

Service Tables

1000-Sheet Finisher (D588)

3000 /2000-Sheet (Booklet) Finisher (D636/D637)

6144Output Check Display Description 001 Upper Relay Motor Upper Transport Motor 002 Lower Relay Motor Lower Transport Motor 003 Exit Motor - 004 Proof Junction Gate SOL Tray Junction Gate Solenoid 005 Lower Tray Lift Motor - 006 Jogger Fence Motor - 007 Stapler Motor - 008 Stapler Hammer - 009 Stapler Junction Gate Solenoid - 010 Positioning Roller Solenoid - 011 Stack Feed-out Motor - 012 Shift Motor - 013 Exit Guide Plate Motor -

6145Output Display Description 001 Entrance Motor - 002 Upper Transport Motor - 003 Lower Transport Motor - 004 Upper/Proof Tray Exit Motor - 005 Clamp Roller Retraction Motor - 006 Shift Roller Motor - 007 Exit Guide Plate Motor - 008 Upper Tray Lift Motor - 009 Stacking Sponge Roller Motor - 010 Jogger Fence Motor - 011 Feed Out Belt Motor - 012 Corner Stapler Movement Motor - 013 Corner Stapler Rotation Motor - 014 Corner Stapler - 015 Proof Junction Gate Solenoid - 016 Stapling Tray Junction Gate Solenoid -

017Stapling Edge Pressure Plate Solenoid

-018 Positioning Roller Solenoid - 019 Booklet Pressure Roller Solenoid - 020 Stack Junction Gate Motor - 021 Fold Unit Bottom Fence Lift Motor - Service Tables022 Booklet Stapler: Front - 023 Booklet Stapler: Rear - 024 Fold Plate Motor - 025 Fold Roller Motor - 026 Positioning Roller Motor - 027 Punch Drive Motor - 028 Punch Movement Motor - 029 Paper Position Sensor Slide Motor -

PRINTER SERVICE TABLES

SP1-XXX (Service Mode)

1001 Bit Switch 001 Bit Switch 1 0 1 bit 0 DFU - - bit 1 DFU - - bit 2 DFU - - bit 3 No I/O Timeout 0: Disable 1: Enable Enable: The MFP I/O Timeout setting will have no effect. I/O Timeouts will never occur. bit 4 SD Card Save Mode 0: Disable 1: Enable Enable: Print jobs will be saved to an SD Card in the GW SD slot. bit 5 DFU - - bit 6 DFU - - bit 7 [RPCS,PCL]: Printable area frame border 0: Disable 1: Enable Enable: The machine prints all RPCS and PCL jobs with a border on the edges of the printable area.

1001 Bit Switch 002 Bit Switch 2 0 1 bit 0 DFU - - bit 1 DFU - - bit 2 Applying a collation Type Shift Collate Normal Collate A collation type (shift or normal) will be applied to all jobs that do not already have a ‘Collate Type’ configured.

bit 3 [PCL5e/c,PS]: PDL Auto Switching 0: Enable 1: Disable Disable: The MFPs ability to change the PDL processor mid-job.

Some host systems submit jobs that contain both PS and PCL5e/c. If Auto PDL switching is disabled, these jobs will not be printed properly.bit 4 DFU - - bit 5 DFU - - bit 6 DFU - - bit 7 DFU - - - If #5-0 is enabled, this Bit Switch has no effect.

- Service Tables

1001 Bit Switch 003 Bit Switch 3 0 1 bit 0 DFU - - bit 1 DFU - - bit 2 [PCL5e/c]: Legacy HP compatibility 0: Disable 1: Enable Enable: Uses the same left margin as older HP models such as HP4000/HP8000.

In other words, the left margin defined in the job (usually "<ESC>*r0A") will be changed to "<ESC>*r1A"bit 3 DFU - - bit 4 DFU - - bit 5 DFU - - bit 6 DFU - - bit 7 DFU - - Service Tables1001 Bit Switch 004 Bit Switch 4 0 1 bit 0 DFU - - bit 1 DFU - - bit 2 DFU - - bit 3 IPDS print-side reversal 0: Disable 1: Enable Enable: Increases printing speed but simplex pages may be printed on the back side of the sheet. bit 4 DFU - - bit 5 DFU - - bit 6 DFU - - bit 7 DFU - -

1001 Bit Switch 005 Bit Switch 5 0 1

bit 0Show "Collate Type", "Staple Type" and "Punch Type" buttons on the operation panel.

Disable

EnableIf enabled, users will be able to configure a Collate Type, Staple Type, and Punch Type from the operation panel. The available types will depend on the device and configured options.

After enabling the function, the settings will appear under: "User Tools > Printer Features > System"bit 1 Multiple copies if a paper size or type mismatch occurs 0: Disable (Single copy)

1: Enable (Multiple copy)If a paper size or type mismatch occurs during the printing of multiple copies, only a single copy is output by default. Using this Bit Switch, the device can be configured to print all copies even if a paper mismatch occurs. bit 2 DFU - - bit 3 [PS] PS Criteria Pattern3 Pattern1 Change the number of PS criterion used by the PS interpreter to determine whether a job is PS data or not.

Pattern3: includes most PS commands.

Pattern1: A small number of PS tags and headersbit 4 Increase max number of the stored jobs to 1000 jobs. Disable (100) Enable (1000) Enable: Changes the maximum number of jobs that can be stored on the HDD via Job Type settings to 1000. The default is 100. bit 5 DFU - - bit 6 Method for determining the image rotation for the edge to bind on.

0: Disable

1: EnableIf enabled, the image rotation will be performed as they were in the specifications of older models for the binding of pages of mixed orientation jobs.

The old models are below:bit 7

Letterhead mode printing

0: Disable1: Enable (Duplex) Routes all pages through the duplex unit.

If this is disabled, simplex pages or the last page of an odd-paged duplex job are not routed through the duplex unit. This could result in problems with letterhead/pre-printed pages.

Only affects pages specified as Letterhead paper.- PCL: Pre-04A models

- PS/PDF/RPCS

re-05S models

1001 Bit Switch 006 Bit Switch 6 DFU - -

1001 Bit Switch 007 Bit Switch 7 0 1

bit 0Print path 0: Disable 1: Enable If enabled, simplex pages (in mixed simplex/duplex PS/PCL5 jobs only) and the last page of an odd paged duplex job (PS, PCL5, PCL6), are always routed through the duplex unit. Not having to switch paper paths increases the print speed slightly. bit 1

to 7

DFU

-

-

Service Tables1001 Bit Switch 008 Bit Switch 8 DFU - -

1001 Bit Switch 009 Bit Switch 9 0 1

bit 0PDL Auto Detection timeout of jobs submitted via USB or Parallel Port (IEEE 1284).

"Disabled (Immediately)"

"Enabled (10 seconds)"To be used if PDL auto-detection fails. A failure of PDL autodetection doesn't necessarily mean that the job can't be printed. This bit switch tells the device whether to time-out immediately (default) upon failure or to wait 10 seconds. bit 1 DFU - - bit 2 Job Cancel Disabled (Not cancelled)

Enabled (Cancelled)If this bit switch, all jobs will be cancelled after a jam occurs.

Note: If this bitsw is enabled, printing under the following conditions might result in problems:bit 3 PCL/PS bypass tray paper rotation (SEF/LEF)

0: Disable

1: EnableThis bitsw causes the device to revert to the behavior of previous generations. It only takes effect if "Bypass Tray Setting Priority" = "Driver/Command".

Previous spec (bitsw=1): If a standard sized paper mismatch occurred in the bypass tray, the MFP always prompted for SEF paper.

If this bitsw=0 (default) then in the event of a standard sized paper mismatch, the MFP will always prompt for paper of the rotation (SEF/LEF) determined by the MFP bypass tray paper setting or by the bypass tray sensor.bit 4 Response to PJL USTATUS when multiple collated copies are printed

0: Disable

1: Enable- Job submission via USB or Parallel Port

- Spool printing (WIM >Configuration > Device Settings > System)

When enabled, if multiple collated copies are printed, the device no longer responds to PJL USTATUS with the number of pages in the current copy. Instead the device will return the total number of pages for all copies. Bit 5

to 7DFU

-

-

1001 Bit Switch 010 Bit Switch 10 0 1 bit 0

to 4

DFU

-

-bit 5 List / Test Print Lock 0: Disable 1: Enable If enabled, you can lock or unlock the [List/Test Print] items under the Pinter Features menu when the Store and Skip Errored Job Function is on. Bit 6 Optional charge machines - - If enabled, you can use the optional charge machines when the Store and Skip Errored Job Function is on.

0: Disable

1: EnableBit 7 DFU - -

1001 Bit Switch 011 Bit Switch 11 0 1 bit 0 List / Test Print menu 0: Disable 1: Enable When enabled, [Multiple Lists] menu is displayed in [List / Test Print] under the Printer Features menu. bit 1 Interrupt printing 0: Job 1: Page Service TablesSelects the interrupt unit for the interrupt printing function.

When you select "0," you can interrupt the printing of a job while being processed.

When you select "1," you can interrupt the printing of a page while being processed.Bit 2

to 7DFU

-

-

1001 Bit Switch 012 Bit Switch 12 0 1 bit 0

to 7

DFU

-

-

1003 [Clear Setting]

1003 001Initialize Printer System Initializes settings in the "System" menu of the user mode. 1003 003 Delete Program

1004 [Print Summary]

1004 001Print Printer Summary Prints the service summary sheet (a summary of all the controller settings).

1006 [Sample/Locked Print] *CTL 0: Linked, 1: On

1006 001Enables and disables the document server. When you select "0," the document server is enabled or disabled in accordance with Copy Service Mode SP5-967. When you select "1," the document server is enabled regardless of Copy Service Mode SP5-967. SCANNER SERVICE TABLES

SP1-xxx (System and Others)

1005 | [Erase margin (Remote Scan)] | ||

| Creates an erase margin for all edges of the scanned image. If the machine has scanned the edge of the original, create a margin. This SP is activated only when the machine uses TWAIN scanning. | |||

| 1005 1 | Range from 0 to 5 mm | *CTL | [0 to 5 / 0 / 1 mm/step ] |

1009 | [Remote scan disable] | *CTL | [0 or 1 / 0 / - ] 0: enable, 1: disable |

| 1009 1 | Enable or disable remote scan. |

1010 | [Non Display Clear Light PDF] | *CTL | [0 or 1 / 0 / - ] 0: Display, 1: Non display |

| 1010 1 | Enable or disable remote scan. |

SP2-XXX (Scanning-image quality)

2021 | [Compression Level (Gray-scale)] | ||

| Selects the compression ratio for grayscale processing mode (JPEG) for the three settings that can be selected at the operation panel. | |||

| 2021 1 | Comp1: 5-95 | *CTL | [5 to 95 / 20 / 1 /step ] |

| 2021 2 | Comp2: 5-95 | [5 to 95 / 40 / 1 /step ] | |

| 2021 3 | Comp3: 5-95 | [5 to 95 / 65 / 1 /step ] | |

| 2021 4 | Comp4: 5-95 | [5 to 95 / 80 / 1 /step ] | |

| 2021 5 | Comp5: 5-95 | [5 to 95 / 95 / 1 /step ] |

2024 | [Compression ratio of ClearLight PDF] | ||

| Selects the compression ratio for clearlight PDF for the two settings that can be selected at the operation panel. | |||

| 2024 1 | Compression Ratio (Normal) | *CTL | [5 to 95 / 25 / 1 /step ] |

2024 2 | Compression Ratio (High comp image) | [5 to 95 / 20 / 1 /step ] |

UPDATING THE FIRMWARE

To update the firmware for this machine, you must have the new version of the firmware downloaded onto an SD (Secure Digital) Card. The SD Card is inserted into SD Card Slot 2 (Lower Slot) on the controller box.BEFORE YOU BEGIN

An SD card is a precision device. Always observe the following precautions when you handle SD cards:- Always switch the machine off before you insert an SD card. Never insert the SD card into the slot with the power on.

- Do not remove the SD card from the service slot after the power has been switched on.

- Never switch the machine off while the firmware is downloading from the SD card.

- Keep SD cards in a safe location where they are not exposed to high temperature, high humidity, or exposure to direct sunlight.

- Always handle SD cards with care. Do not bend or scratch them. Do not let the SD card get exposed to shock or vibration.

- Make sure that the write protection of an SD card is unlocked when you download an application to it. If not, downloading fails and a download error (e.g. Error Code 44) occurs during a firmware upgrade.

Keep the following points in mind when you use the firmware update software: - "Upload" means to send data from the machine to the SD card. "Download" means to send data from the SD card to the machine.

- To select an item on the LCD, touch the appropriate button on the soft touch-screen of the LCD, or, press the appropriate number key on the 10-key pad of the operation panel. For example, when "Exit (0)" shows on the screen you can touch the Exit button on the screen, or, press the "0" button on the operation panel of the copier.

- Make sure that the machine is disconnected from the network to prevent a print job for arriving while the firmware update is in progress before you start the firmware update procedure.

UPDATING FIRMWARE

Preparation- If the SD card is blank, copy the entire "romdata" folder onto the SD card.

- If the card already contains the "romdata" folder, copy the "D129" folder onto the card.

Service Tables

1. Turn the main power switch off.

Remove the controller cover ( x 2).

2.

- Insert the SD card into SD Card Slot 2 (Lower Slot) [A]. Make sure the label on the SD card faces the rear side of the machine.

- Slowly push the SD card into the slot so it locks in place. You will hear it click. Make sure the SD card locks in place.

- To remove the SD, push it in to unlock the spring lock. Then release it so it pops out of the slot.

- Disconnect the network cable from the copier if the machine is connected to a network.

- Switch the main power switch on. After about 45 seconds, the initial version update screen appears on the LCD in English.

- On the screen, touch the button or press the corresponding number key on the operation panel to select the item in the menu that you want to update.

ROM/NEW What it means

ROM:Tells you the number of the module and name of the version currently installed. The first line is the module number, the second line the version name.

NEW:Tells you the number of the module and name version on the SD card. The first line is the module number, the second line the version name.

- Controller, engine and operation panel firmware cannot be updated at the same time. It is recommended to update firmware modules one by one.

- Touch "UpDate (#)" (or

) to start the update.

- While downloading is in progress, the LCD will display "Loading". When downloading has been completed, the panel will display "update done".

- For operation panel software, the Start key lights red while downloading is in progress, and then lights green again after downloading is completed.

- The "Update is Done" message appears on the operation panel after completing the updating. The message differs depending on the firmware that has been updated.

- Switch the copier main power switch off when you see the "Update is Done" message or follow the procedure that is displayed on the operation panel.

- Press in the SD card to release it. Then remove it from the slot.

- Switch the copier on for normal operation.

- Error Messages

The error code consists of the letter "E" and a number. The example above shows error "E24" displayed. For details, refer to the Error Message Table."Handling Firmware Update Errors" in this section)

Firmware Update Error

If a firmware update error occurs, this means the update was cancelled during the update because the module selected for update was not on the SD card.

Service Tables

Recovery after Power Loss

If the ROM update is interrupted as a result of accidental loss of power while the firmware is updating, then the correct operation of the machine cannot be guaranteed after the machine is switched on again. If the ROM update does not complete successfully for any reason, then in order to ensure the correct operation of the machine, the ROM update error will continue to show until the ROM is updated successfully.

In this case, insert the card again and switch on the machine to continue the firmware download automatically from the card without the menu display.HANDLING FIRMWARE UPDATE ERRORS

Error Message Table

| Code | Meaning | Solution |

20 | Cannot map logical address | Make sure the SD card is installed correctly, or use a different SD card. |

| 21 | Cannot access memory | HDD connection incorrect or replace HDD. |

22 | Cannot decompress compressed data | Incorrect ROM data on the SD card, or data is damaged. |

23 | Error occurred when ROM update program started | Controller program defective. If the second attempt fails, replace controller board. |

24 | SD card access error | Make sure the SD card is inserted correctly, or use a different SD card. |

30 | No HDD available for stamp data download | HDD connection incorrect or replace HDD. |

31 | Data incorrect for continuous download | Insert the SD card with the remaining data required for the download, the re-start the procedure. |

32 | Data incorrect after download interrupted | Execute the recovery procedure for the intended module download, then repeat the installation procedure. |

33 | Incorrect SD card version | Incorrect ROM data on the SD card, or data is corrupted. |

34 | Module mismatch - Correct module is not on the SD card) | SD update data is incorrect. Acquire the correct data (Japan, Overseas, OEM, etc.) then install again. |

| Code | Meaning | Solution |

35 | Module mismatch – Module on SD card is not for this machine | SD update data is incorrect. The data on the SD card is for another machine. Acquire correct update data then install again. |

36 | Cannot write module – Cause other than E34, E35 | SD update data is incorrect. The data on the SD card is for another machine. Acquire correct update data then install again. |

40 | Engine module download failed | Replace the update data for the module on the SD card and try again, or replace the BCU board. |

42 | Operation panel module download failed | Replace the update data for the module on the SD card and try again, or replace the LCDC. |

43 | Stamp data module download failed | Replace the update data for the module on the SD card and try again, or replace the hard disks. |

44 | Controller module download failed | Replace the update data for the module on the SD card and tray again, or replace controller board. |

50 | Electronic confirmation check failed | SD update data is incorrect. The data on the SD card is for another machine. Acquire correct update data then install again. |

UPLOADING/DOWNLOADING NVRAM DATA

The content of the NVRAM can be uploaded to and downloaded from an SD card.

UPLOADING NVRAM DATA (SP5-824)

1. Turn off the main switch.

Remove the controller cover [A] ( x 2).

2.

- Insert the SD card into SD card slot 2 (Lower Slot) [A].

- Turn on the main switch.

- Execute SP5-824.

- Press "1" to start uploading the NVRAM data.

DOWNLOADING NVRAM DATA (SP5-825)

- Total counter

- C/O, P/O Counter

- Duplex, A3/DLT/Over 420 mm, Staple and Scanner application scanning counters (system settings).

- Engine SP data

Service Tables

1. Turn off the main switch.

Remove the controller cover [A] ( x 2).

2.

- Plug the SD card into SD card slot 2 (Lower Slot) [A].

- Turn on the main switch.

- Execute SP5-825.

- Press "1" to start downloading the NVRAM data.

- Note that the following errors could occur during downloading:

- If a card is not installed in the card slot and a message tells you that downloading cannot proceed, you cannot execute downloading, even by pressing "1".

- If the correct card for the NVRAM data is not inserted in the card slot, after you press "1" a message will tell you that downloading cannot proceed because the card is abnormal and the execution will halt.

SELF-DIAGNOSTIC MODE

SELF-DIAGNOSTIC MODE AT POWER ON

As soon as the main machine is powered on, the controller waits for the initial settings of the copy engine to take effect and then starts an independent self-diagnostic test program. The

Service Tables

self-diagnostic test follows the path of the flow chart shown below and checks the CPU, memory, HDD, and so on. An SC code is displayed in the touch panel if the self-diagnostic program detects any malfunction or abnormal condition.SELF-DIAGNOSTIC TEST FLOW

DETAILED SELF-DIAGNOSTIC MODE

In addition to the self-diagnostic test initiated every time the main machine is powered on, you can set the machine in a more detailed diagnostic mode manually in order to test other components or conditions that are not tested during self-diagnosis after power on. The following device is required in order to put the machine in the detailed self-diagnosis mode.

No. Name G02119350 Parallel Loopback Connector

EXECUTING DETAILED SELF-DIAGNOSIS

- Follow this procedure to execute detailed self-diagnosis.

- Switch off the machine, and connect the parallel loopback device to the Centronics I/F port.

- Hold down

, press and hold down

, and then while pressing both keys at the same time, switch on the machine.

, and then while pressing both keys at the same time, switch on the machine.

- Service Tables

You will see "Now Loading" on the touch-panel, and then you will see the results of the test. A report is printed every time a detailed self-diagnostic test is executed, whether errors were detected or not.

USING THE DEBUG LOG

OVERVIEW

This machine provides a Save Debug Log feature that allows the Customer Engineer to save and retrieve error information for analysis.

Every time an error occurs, debug information is recorded in volatile memory but this information is lost when the machine is switched off and on.

To capture this debug information, the Save Debug Log feature provides two main features:

- Switching on the debug feature so error information is saved directly to the HDD for later retrieval.

- Copying the error information from the HDD to an SD card.

When a user is experiencing problems with the machine, follow the procedure below to set up the machine so the error information is saved automatically to the HDD. Then ask the user to reproduce the problem.

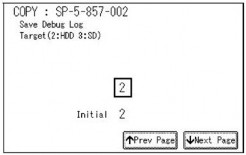

SWITCHING ON AND SETTING UP SAVE DEBUG LOG

- The debug information cannot be saved the until the "Save Debug Log" function has been switched on and a target has been selected.

- Enter the SP mode.

- Under "5857 Save Debug Log", press "1".

- On the control panel keypad, press "1" then press

. This switches the Save Debug Log feature on.

- The default setting is "0" (OFF). This feature must be switched on in order for the debug information to be saved.

- Next, select the target destination where the debug information will be saved. Under "5857 Save Debug Log", touch "2 Target", enter "2" with the operation panel key to select the hard disk as the target destination, then press

.

- Select "3 SD Card" to save the debug information directly to the SD card if it is inserted in Slot 2 (Lower Slot).

- Now touch "5858" and specify the events that you want to record in the debug log. SP5858 (Debug Save When) provides the following items for selection.

1

Engine SC ErrorSaves data when an engine-related SC code is generated.

2

Controller SC ErrorSaves debug data when a controller-related SC Code is generated.

3

Any SC ErrorSaves data only for the SC code that you specify by entering code number. 4 Jam Saves data for jams.

Service Tables

- More than one event can be selected.

Example 1: To Select Items 1, 2, 4

Touch the appropriate items(s). Press "ON" for each selection. This example shows "Engine SC Error" selected.

Example 2: To Specify an SC Code

Touch "3 Any SC Error", enter the 3-digit SC code number with the control panel number keys, then press. This example shows an entry for SC670.

- For details about SC code numbers, please refer to the SC tables in Section "4. Troubleshooting"

- More than one event can be selected.

- Next, select the one or more memory modules for reading and recording debug information. Touch "5859".

Under "5859" press the appropriate key item for the module that you want to record. Enter the appropriate 4-digit number, then press.

- Refer to the two tables below for the 4-digit numbers to enter for each key. The example below shows "Key 1" with "2222" entered.

-

- Digit Entries for Keys 1 to 10

Key No. Copy Printer Scanner Web 1 2222 (SCS) 2 2223 (SRM) 3 256 (IMH) 4 1000 (ECS) 5 1025 (MCS) 6 4848(COPY) 4400 (GPS) 5375 (Scan) 5682 (NFA) 7 2224 (BCU) 4500 (PDL) 5682 (NFA) 6600 (WebDB)

84600 (GPS-PM)

3000 (NCS)

3300 (PTS)9 2000 (NCS) 2000 (NCS) 6666 (WebSys) 10 2224 (BCU) 2000 (NCS)

- The default settings for Keys 1 to 10 are all zero ("0").

Acronym Meaning Acronym Meaning ECS Engine Control Service NFA Net File Application GPS GW Print Service PDL Printer Design Language

GSP-PMGW Print Service – Print Module

PTS

Print ServerIMH Image Memory Handler SCS System Control Service

MCS

Memory Control Service

SRMSystem Resource Management

NCS

Network Control Service

WebDBWeb Document Box (Document Server)

Service Tables

The machine is now set to record the debugging information automatically on the HDD (the target selected with SP5-857-002) for the events that you selected SP5-858and the memory modules selected with SP5-859.

Please keep the following important points in mind when you are doing this setting: - Note that the number entries for Keys 1 to 5 are the same for the Copy, Printer, Scanner, and Web memory modules.

- The initial settings are all zero.

- These settings remain in effect until you change them. Be sure to check all the settings, especially the settings for Keys 6 to 10. To switch off a key setting, enter a zero for that key.

- You can select any number of keys from 1 to 10 (or all) by entering the corresponding 4-digit numbers from the table.

- You cannot mix settings for the groups (COPY, PRINTER, etc.) for 006to010. For example, if you want to create a PRINTER debug log you must select the settings from the 9 available selections for the "PRINTER" column only.

- One area of the disk is reserved to store the debug log. The size of this area is limited to 4 MB.

Retrieving the Debug Log from the HDD- Insert the SD card into Slot 2 (Lower Slot).

- Enter the SP mode and execute SP5857 009 (Copy HDD to SD Card (Latest 4 MB) to write the debugging data to the SD card.

- The SD card can hold up to 4MB of data. If the debugging data is larger than 4MB, you can switch to another SD card.

- Use a card reader to copy the file and send it for analysis to your local Ricoh representative by email, or just send the SD card by mail.

Recording Errors Manually

Since only SC errors and jams are recorded to the debug log automatically, for any other errors that occur while the customer engineer is not on site, please instruct customers to perform the following immediately after occurrence to save the debug data. Such problems would include a controller or panel freeze.

- In order to use this feature, the customer engineer must have previously switched on the Save Debug Feature (SP5857-001) and selected the hard disk as the save destination (SP5857-002).

- When the error occurs, on the operation panel, press

(Reset Key).

- On the control panel, enter "01" then hold down

for at least 3 sec. until the machine beeps then release. This saves the debug log to the hard disk for later retrieval with an SD card by the service representatives.

- Switch the machine off and on to resume operation.

- The debug information for the error is saved on the hard disk so the service representatives can retrieve it on their next visit by copying it from the HDD to an SD card.

TROUBLESHOOTING

RE V IS ION H IST ORY Page Date Added/ Updated/ New None TROUBLESHOOTING

SERVICE CALL CONDITIONS

SUMMARY

There are 4 levels of service call conditions.

Level Definition Reset Procedure

ATo prevent damage to the machine, the main machine cannot be operated until the SC has been reset by a service representative (see the note below). Enter SP mode, use SP 5810, touch [Execute], and then turn the main power switch off and on.

BSCs that disable only the features that use the defective item. Although these SCs are not shown to the user under normal conditions, they are displayed on the operation panel only when the defective feature is selected.

Turn the operation switch or main switch off and on.

C

The SC history is updated. The machine can be operated as usual.The SC will not be displayed. Only the SC history is updated.

DTurning the main switch off then on resets SCs displayed on the operation panel. These are

re-displayed if the error occurs again.Turn the operation switch off and on.

Also see below.

Trouble- shooting

When a Level "D" SC code occurs

When a Level D SC occurs, a screen opens on the operation panel to tell the operator:

- An error occurred

- The job in progress will be erased

- The machine will reboot automatically after approximately 30 seconds.

The operator can wait until the machine reboots automatically or touch "Reset" on the screen to reset the machine immediately and go back to the copy screen.

If the operator does not touch "Reset"

The next message tells the operator that the machine will reset automatically and that the previous job was lost and must be started again. After reading the message, the operator touches "Confirm" on the screen. The next screen shows the number and title of the SC code, and stops until the operator turns the machine off and on.

If the operator touches "Reset"

If the operator touches "Reset" to bypass the 30-second interval for the machine to reboot, the machine reboots immediately and the operation panel displays the copy screen.

- Do not try to use the operation panel during an automatic reboot.

- If the Remote Service System is in use, the SC code is sent immediately to the Service Center.

SC CODE DESCRIPTIONS

- If a problem concerns a circuit board, disconnect and reconnect the connectors and then test the machine. Often a loose or disconnected harness is the cause of the problem. Always do this before you decide to replace the PCB.

- If a motor lock error occurs, check the mechanical load before you decide to replace the motor or sensors.

- When a Level "A" or "B" SC occurs while in an SP mode, the machine cannot display the SC number. If this occurs, check the SC number after leaving the SP mode.

- The machine reboots automatically when the machine issues a Level "D" SC code. This is done for Level "D" SC codes only.

- Never turn off the main power switch when the power LED is lit or flashing. To avoid damaging the hard disk or memory, press the operation switch to switch the power off, wait for the power LED to go off, and then switch the main power switch off.

- The main power LED lights or flashes while the platen cover or ARDF is open, while the main machine is communicating with a facsimile or the network server, or while the machine is accessing the hard disk or memory for reading or writing data.

SC Tables: SC1xx

101 | D | Exposure lamp error |

| -001: Shading at AGC -002: Shading at scanning

| ||

| ||

| The peak white level is less than 64/255 digits (8 bits) when scanning the shading plate. (The shading data peak does not reach the specified threshold) |

120 | D | Scanner home position error 1 |

| The scanner home position sensor does not detect the "OFF" condition during initialization or copying. | ||

|

121 | D | Scanner home position error 2 |

| The scanner home position sensor does not detect the "ON" condition during initialization or copying. | ||

|

141 | D | Black level detection error |

| The black level cannot be adjusted within the target value during the zero clamp. | ||

|

142 | D | White level detection error |

| The white level cannot be adjusted within the target during auto gain control. | ||

|

144 | D | SBU connection error |

| The SBU connection cannot be detected at power on or recovery from the energy save mode. | ||

|

161 | D | IPU error |

| The error result of self-diagnostic by the ASIC on the IPU is detected. | ||

|

162 | D | IPU PCIE Communication error |

| The link up interrupt did not proceed from the LYRA when the main switch was turned on or when recovering from the energy saver mode. | ||

|

165 | D | Copy Data Security Unit error |

| The copy data security board is not detected when the copy data security function is set "ON" with the initial setting. A device check error occurs when the copy data security function is set to "ON" with the initial setting. | ||

|

202 | D | Polygon motor error 1: ON timeout |

| The polygon mirror motor does not reach the targeted operating speed within 10 sec. after turning on or changing speed | ||

203 | D | Polygon motor error 2: OFF timeout |

| The polygon mirror motor does not leave the READY status within 3 sec. after the polygon motor switched off. | ||

204 | D | Polygon motor error 3: XSCRDY signal error |

| The SCRDY_N signal remains HIGH for 200 ms while the LD unit is firing. | ||

|

220 | D | Laser synchronizing detection error: start position LD0 |

| The laser synchronizing detection signal for the start position of the LDB is not output for two seconds after LDB unit turns on while the polygon motor is rotating normally | ||

|

221 | D | Laser synchronizing detection error: start position LD1 |

| The laser synchronizing detection signal for the start position of the LDB is not output for two seconds after LDB unit turns on while the polygon motor is rotating normally. | ||

|

230 | D | FGATE ON error |

| The FGATE signal does not assert within the prescribed time. (The IPU generates the FGATE signal and sends it to the LD unit when the registration sensor switches on.) | ||

231 | D | FGATE OFF error |

| The FGATE signal does not assert within the prescribed time. (The IPU generates the FGATE signal and sends it to the LD unit when the registration sensor switches on.) | ||

|

240 | C | LD error |

| The IPU detected a problem at the LD unit. | ||

|

270 | D | GAVD communication error |

| ||

|

302 | D | Charge roller bias leak |

| A charge roller bias leak signal was detected. | ||

|

304 | D | Charge roller bias correction leak |

| The charge roller bias correction is performed twice even if the maximum charge roller bias (-2000V) is applied to the roller. | ||

|

320 | D | Development roller bias leak |

| The development roller bias leak is detected for 60 ms after the high voltage has been supplied to the development unit. | ||

|

324 | D | Development paddle motor error |

| The machine detects a lock signal error from the development puddle motor for 2 seconds after the drum motor has turned on. | ||

|

350 | D | ID sensor pattern test error |

One of the following readings occurred 10 times in the ID sensor output when the ID sensor pattern was checked:

| ||

|

351 | D | ID sensor Vsg test error |

| When the ID sensor was checked, the ID sensor output voltage is 5.0V while the LED current value is 0. | ||

|

355 | C | Grayscale measurement error |

| When the grayscale control result is the maximum and it does not operate correctly and these cases are detected 15 times. | ||

|

360 | D | TD sensor (Vt) error 1 |

| The following condition occurs thirty times consecutively during printing. Vt is less than 0.5V or 4.8V or more | ||

|

372 | D | TD sensor adjustment error |

| Vts is less than 1.8V or 4.8V or more during TD sensor initialization. | ||

|

396 | D | Drum motor error |

| The machine detects a lock signal error from the drum motor for 2 seconds after the drum motor turned on. | ||

|

SC Tables: SC4xx

400 | D | Vsg adjustment error |

| Vsg is more than 4.2V or 3.8V or less when the machine adjusts Vsg value. | ||

|

440 | D | Transfer belt bias error |

| The feed back bias from the transfer belt is more than 4V for 60 msec while the transfer belt bias is output. The A/D conversion level is 20 or less for 60 msec. The PWM duty is 24% or more for 60 msec. | ||

|

441 | D | Transfer/Development motor error |

| The machine detects a lock signal error from the transfer/development motor for a continuous 20 times after the transfer/development motor turned on. | ||

|

Last edited: