Replacement and Adjustment

When attaching the Mylar, follow the steps below.

When applying the Mylar, be sure not to stretch the FFC.

Applying the Mylar while stretching the FFC causes the circuit board to be deformed.

Replacement and Adjustment

When the bottle is replaced before the machine stops due to a full bottle, it is necessary to reset the PM counter manually (set SP3-701-142 to “1” before replacing the bottle, then switch the power off).

0: new unit detection flag OFF, 1: new unit detection flag ON

Replacement and Adjustment

Input data for TM/ID Sensor: F into SP3-333. Input data for TM/ID sensor: C into SP3-334. Input data for TM/ID sensor: R into SP3-335.

Replacement and Adjustment

Replacement and Adjustment

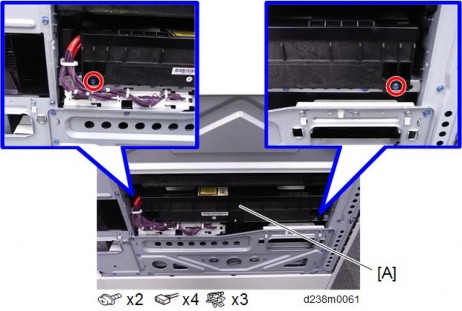

Rear cover (page 4-14)

Controller box cover (page 4-182)

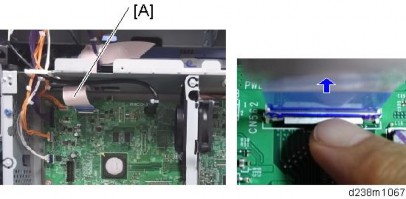

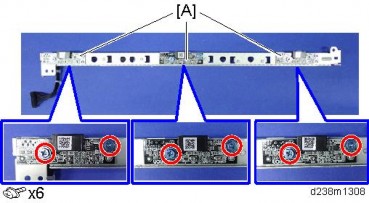

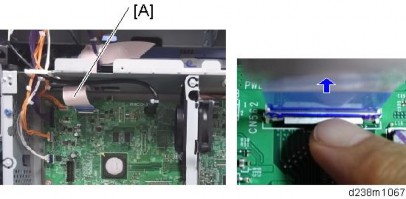

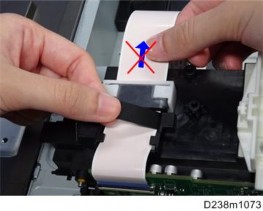

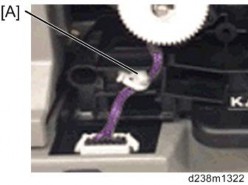

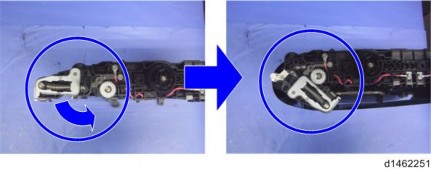

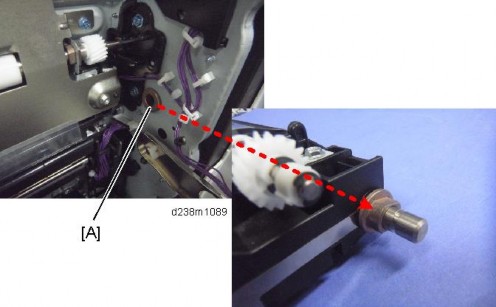

While pressing the lock release lever, pull out the FFC [A].

When Changing the FFC

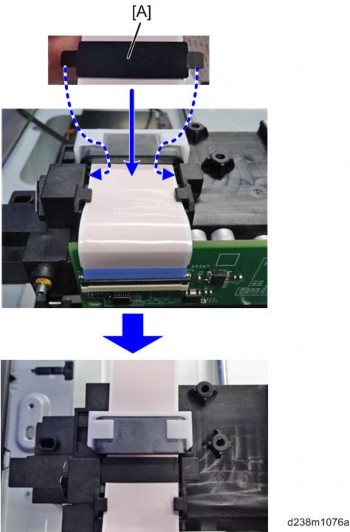

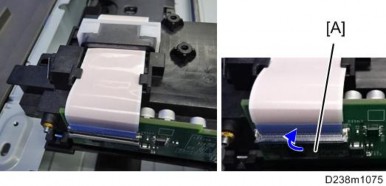

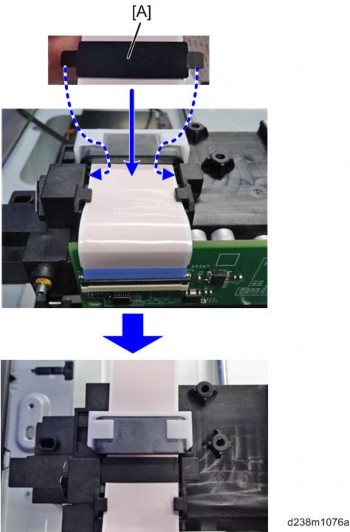

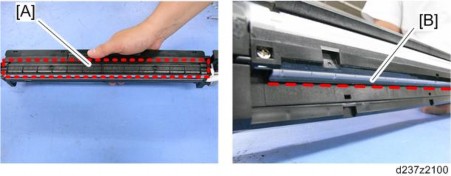

When changing the FFC, stick the Mylar [A] to the new FFC.

When attaching the Mylar, follow the steps below.

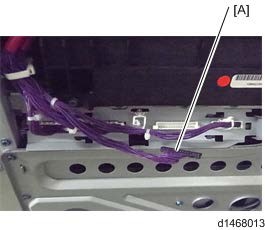

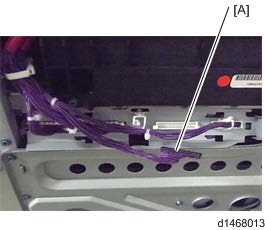

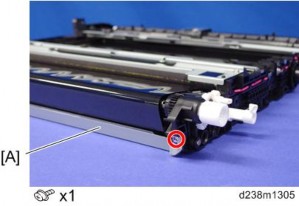

Feed the FFC through the ferrite core [A].

Connect the FFC to the scanner carriage’s connector, and then lift the lever [A] to lock it.

Attach the Mylar [A] to the FFC from above, and then insert the tabs at both ends of the Mylar into the gaps in the FFC holder to secure it in position.

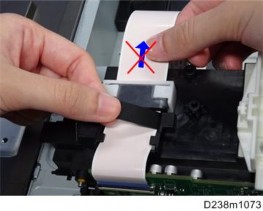

When applying the Mylar, be sure not to stretch the FFC.

Applying the Mylar while stretching the FFC causes the circuit board to be deformed.

Replacement and Adjustment

LASER UNIT

- Turn off the main power switch and unplug the machine before beginning any of the procedures in this section. Laser beams can cause serious eye injury.

- Caution Decals

- Decal Location

LASER UNIT

- A polygon mirror motor protection bracket and a red tag are attached to each new laser unit. Remove these before you install the new unit.

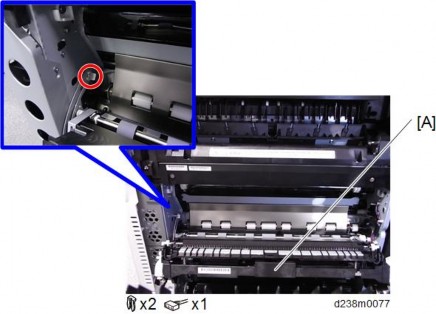

Before Replacement

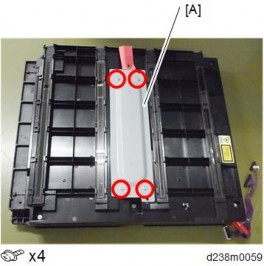

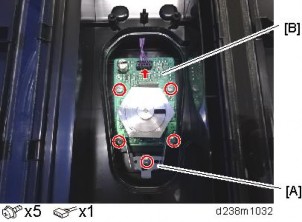

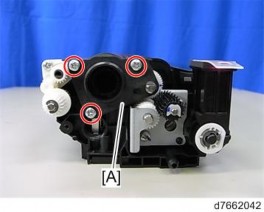

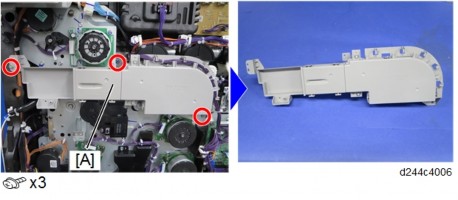

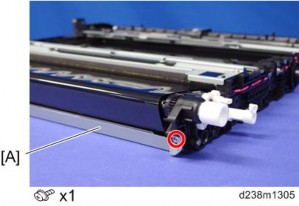

Remove the polygon mirror motor cover [A] from the new laser unit.

Replacement and Adjustment

Polygon mirror motor bracket [A], Red tag

[*]Reattach the polygon mirror motor cover.

Removing

Left cover (page 4-12)

Laser unit [A]

Installing a New Laser Unit

Insert the new laser unit in the main body carefully.

Connect all harnesses except the laser optics positioning motor harness [A] (2nd from right).

Reassemble the machine.

Adjustment after Replacing the Laser Unit

Close the front cover and attach the left cover.

- Attach the left cover before turning on the main power switch. Laser beams can seriously damage your eyes.

Plug in and turn on the main power switch.

Download the data of the new laser unit to the main body with SP2-110-005. 4. Check that SP2-119-001 to 003 is "0."

- If it is not "0", perform SP2-110-005 again.

- If it is not executed correctly, outputs will be abnormal (magnification and color registration errors), and SC 285 may occur.

Turn off the main power switch and disconnect the power cord.

Remove the left cover and attach the laser optics positioning motor harness [A].

Close the left cover.

Plug in and turn on the main power switch.

Select [14: Trimmed area] in SP2-109-003, and then press [OK].

Press [Copy Window], and then print the test pattern in the copy screen.

- Check if the margin on either side on the output (14: Trimmed area) is less than 4±1 mm or not. If it is not within these limits, change the reference value (Bk) of the main scanning magnification adjustment (SP2-102-001 to -003).

- Adjust the values of the main scanning magnification only for Bk (black). It is not necessary to adjust other color’s values (cyan, magenta, yellow) because other colors are automatically adjusted in relation to the setting for Bk.

- Input the same value for each SP (SP2-102-001 to -003) even though there are three SPs of the main scanning magnification adjustment for the standard, middle and low line speed which are used for each paper type.

- Check if the margin on the left side on the output (14: Trimmed area) is less than 2±1 mm or not. If it is not within these limits, change the reference value (Bk) of the registration adjustment (SP2-101-001).

- Check if the margin on either side on the output (14: Trimmed area) is less than 4±1 mm or not. If it is not within these limits, change the reference value (Bk) of the main scanning magnification adjustment (SP2-102-001 to -003).

Set SP2-109-003 to "0: None" after adjusting the main scanning magnification and registration.

Perform line adjustment.

SP2-111-004: Forced Line Position Adj. Mode d

The result can be checked with SP2-194-007 (MUSIC Execution Result Execution Result) (0: Success, 1: Failure).

Also, results for each color can be checked with SP2-194-010 to 013 (1: Completed successfully).Exit the SP mode.

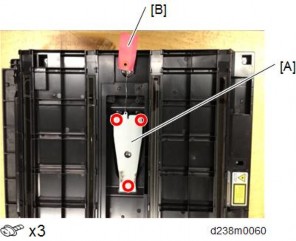

[*]POLYGON MIRROR MOTOR

Laser Unit (page 4-50)

Polygon mirror motor cover [A]

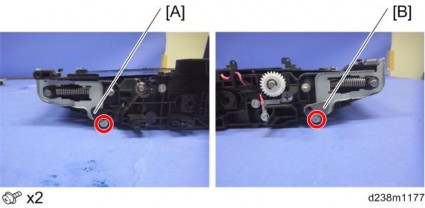

Polygon mirror motor holder [A], Polygon mirror motor

Adjustment after Replacing the Polygon Mirror Motor

SP2-111-004: Forced Line Position Adj. Mode d

The result can be checked with SP2-194-007 (MUSIC Execution Result Execution Result) (0: Success, 1: Failure).

Also, results for each color can be checked with SP2-194-010 to 013.

[*]SP DESCRIPTIONS

SP2-110-005 (Writing Unit Adj. Transfer)

Execution flag to download adjustment values of laser unit to the main unit’s SP. Must be executed when replacing the laser unit or assembling the main unit.

SP2-119-001 to 003 (Skew Adjustment Display)

Displays the current skew correction value for each color.

SP2-109-003 (Test Pattern: Pattern Selection)

Selects the test pattern.

SP2-102-001 to -003 (Magnification Adjustment: Bk)

Adjusts main scan lower speed scale for BK. Value increase: image stretches.

Value decrease: image shrinks

CMY color scale will fit to standard BK speed after executing MUSIC; BK color will have a different scale in the image without executing MUSIC after this SP.

SP2-101-001 (Registration Correction: Color Main Dot: Bk)

Adjusts main scan registration for BK.

Value increase: image shifts to the right facing the paper. Value decrease: image shifts to the left facing the paper.

CMY colors are adjusted to the BK color position if MUSIC is done after this SP.

SP2-111-004 (Forced Line Position Adj. Mode d)

Executes the fine line position adjustment and rough line position adjustment.

SP2-194-007 (MUSIC Execution Result Execution Result)

Displays the result of MUSIC adjustment. 0: Success, 1: Failure

SP2-194-010 to 013 (MUSIC Execution Result: Error Result C, M, Y, K)

Displays the result code of MUSIC adjustment for each color.

Replacement and Adjustment

Detection Result

Meaning0 MUSIC not executed

1Correction Succeeded: Sampling is conducted correctly and the correction is completed 2 Sampling Failed (When the MUSIC pattern failed to be detected)

3Detection Patterns Lacking (When the number of lines detected is smaller than the fixed number)

4The sampled data is beyond the correction range. (Calculated correction value is just out of range) 5 The sampled data is beyond the correction range. - A polygon mirror motor protection bracket and a red tag are attached to each new laser unit. Remove these before you install the new unit.

[*]PCDU

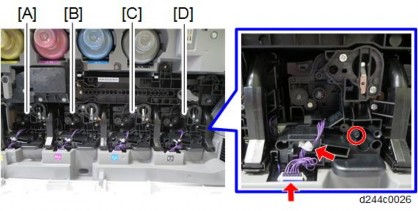

PCDU

- When installing a complete brand-new PCDU, it is not necessary to set SP3-701: New Development Unit detection

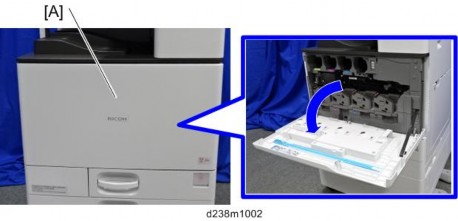

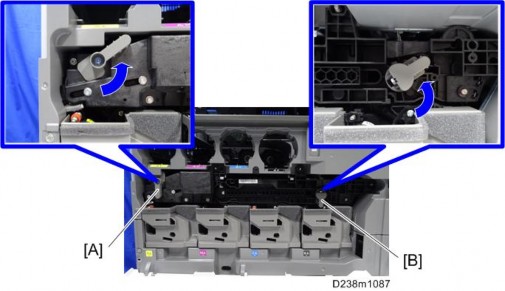

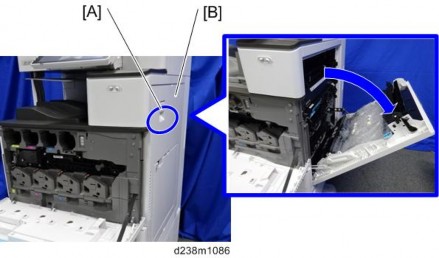

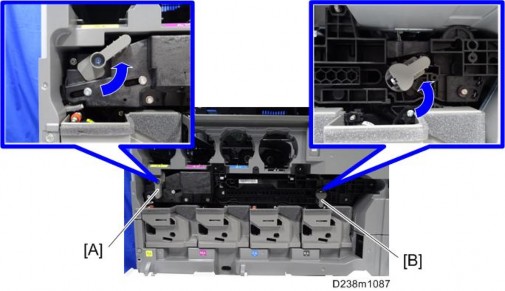

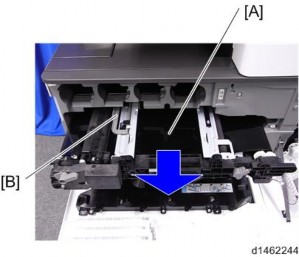

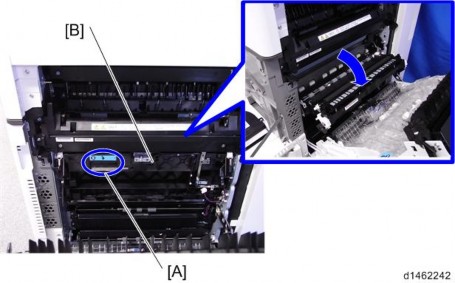

Open the front cover [A].

Image Transfer front cover [A]

Replacement and Adjustment

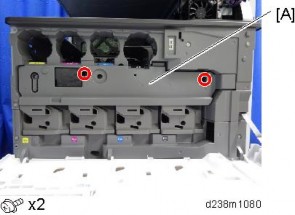

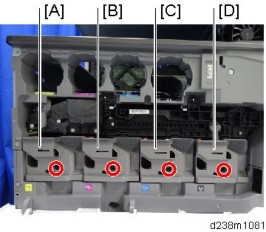

PCDU cover.

[A] Y x 1

[TD]M[/TD]

[TD]x 1[/TD]

[TR]

[TD][C][/TD]

[TD]C[/TD]

[TD]x 1[/TD]

[/TR]

[TR]

[TD][D][/TD]

[TD]K[/TD]

[TD]x 1[/TD]

[/TR]

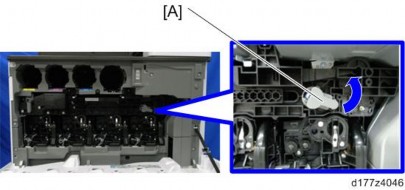

[*]Release the lock of the image transfer contact lever [A].

[*]PCDU.

[A] Y x 1,

x 1, x 1

[TD]M[/TD]

[TD]x 1,[/TD]

[TD]x 1,[/TD]

[TD]x 1[/TD]

[TR]

[TD][C][/TD]

[TD]C[/TD]

[TD]x 1,[/TD]

[TD]x 1,[/TD]

[TD]x 1[/TD]

[/TR]

[TR]

[TD][D][/TD]

[TD]K[/TD]

[TD]x 1,[/TD]

[TD]x 1,[/TD]

[TD]x 1[/TD]

[/TR]

- When attaching the PCDU, clamp the harness so that the bind [A] comes above the clamp.

Adjustment after Replacing the PCDU

Turn ON the main power.

Do the "Automatic Color Calibration (ACC)" for the copier mode & printer mode as follows:

- "User Tools" icon > "Machine Features" > "Maintenance" > "Auto Color Calibration" > "Start"

- Print the ACC test pattern.

- Put the printout on the exposure glass.

- Put 10 sheets of white paper on the test chart. This ensures the precise ACC adjustment.

- Close the SPDF/ARDF or the platen cover.

- Press "Start Scanning" on the LCD. Then, the machine starts the ACC.

Exit the User Tools mode.

[*]PCU/DEVELOPMENT UNIT

Before Replacing a PCU

- In the PCU for MP C2504/C2004 and the PCU for MP C6004/C5504/C4504/C3504/C3004, the charging method is different. Variations in the charge voltage must be corrected when a PCU is replaced.

- Because of this, before replacing a PCU, do the procedure shown below. The main points are as follows.

- Input the charge voltage correction value for the new PCU.

- The machine will optimize SP settings related to imaging using process control, after you input the charge voltage correction value and replace the PCU.

Set SP3-701: New PCU detection to “1” before replacing the PCU. SPs for manual new unit

Item SP

PCUBlack: SP3-701-002 Cyan: SP3-701-025 Magenta: SP3-701-048 Yellow: SP3-701- 071

0: new unit detection flag OFF, 1: new unit detection flag ONCheck the charge voltage correction value printed on the label attached to the new PCU. This value is adjusted for each PCU.

- When installing a complete brand-new PCDU, it is not necessary to input the correction value.

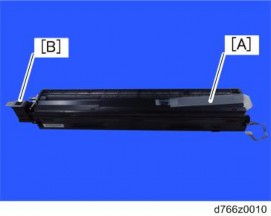

A Bar code B PCU Lot No. C Correction value D Last three digits of SP number E SP No.

- When installing a complete brand-new PCDU, it is not necessary to input the correction value.

Input the value (located at [C] on the decal as shown above) into SP2-005 as shown below.

SPs for charge voltage correction before replacing PCU

SP No. (SP name) K SP2-005-235 (Correction Coefficient c1: K) C SP2-005-236 (Correction Coefficient c1: C) M SP2-005-237 (Correction Coefficient c1: M) Y SP2-005-238 (Correction Coefficient c1: Y)

Check SP2-005 to make sure that you have input the correct values. Check that they are the same as the values on the labels in step 2.

Turn the power OFF.

Replace the PCU.

Turn the power ON. (Process control is done automatically.)

- If you replace the PCU without inputting the correction value, do the following procedure:

- Case 1: When you set SP3-701 to “1”

- Input the PCU correction value.

- Execute process control manually with SP3-011-001 in order to adjust the machine settings with the PCU correction value.

- Case 2: When you did not set SP3-701 to “1” 1. Set SP3-701 to “1”.

- Case 1: When you set SP3-701 to “1”

- If you replace the PCU without inputting the correction value, do the following procedure:

- Input the PCU correction value.

- Turn the power OFF. Note that process control will start automatically.

Before Replacing a Development Unit

Set SP3-701: New unit detection to “1” before replacing the development unit. SPs for manual new unit

Item SP

Development unitBlack: SP3-701-003 Cyan: SP3-701-026 Magenta: SP3-701-049 Yellow: SP3-701- 072

0: new unit detection flag OFF, 1: new unit detection flag ONSwitch the power OFF. Then replace the development unit and switch the power ON.

- Replacing the development unit resets not only the development unit counter, but also the PCU counter. However, if you change the SP setting (SP3-701) before you replace the development unit, the PM counter of the development unit is reset, but the PM counter of the PCU is not reset.

- Therefore, before you replace the development unit, the manual new unit setting

Replacement

PCDU (page 4-58)

Release the connecting part (front) [A]

x 2) and harness .

Cover [A] ( x 1).

3.

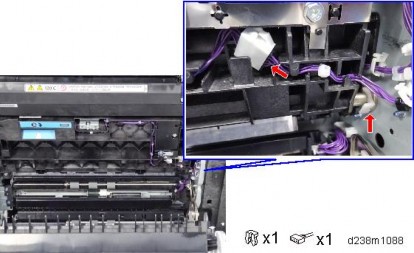

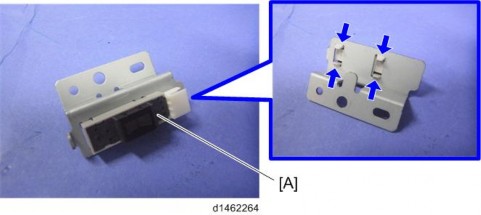

- Be careful not to break the plate (shown by the red arrow).

- Handle with care to prevent deformation of the plate. Deformation can cause unstable images due to contact failure. Be sure to attach this cover to the PCDU and install the PCDU in the mainframe.

- Be careful not to break the plate (shown by the red arrow).

Connecting part (rear) [A]

x 3).

Separate PCU [A] and development unit .

Replacement and Adjustment

- When holding the development unit, be sure to obey the following three DO NOTs:

DO NOT touch the development roller housing [A]. Doing so will deform the development roller housing, which causes the development roller to be scratched.

DO NOT touch the doctor blade . The doctor blade is an extremely sharp-edged blade, made with a high precision to work properly. So touching the blade causes physical injury as well as deformation of the blade assembly which causes a malfunction of the development unit.

[*]DO NOT touch the development roller. Doing so develops a fingerprint on the paper.

[*]Hold the development unit as shown below:

[*]When separating the PCU and development unit, the drum may come off and this

could cause a toner spillage. Hold the PCU [A] with the drum side up as shown below to prevent toner spillage.

Notes for Assembling PCU/Development Unit

Pay close attention not to spill any toner on the charge roller when assembling.

[*]Remove the heat seal [A] after replacing the PCDU.

[*]Remove the cap pasted on the toner port when replacing the PCDU.

Method for Checking after Replacement

Before installing, rotate the drum in the blue arrow direction, to ensure that toner lines do not occur.

Replacement and Adjustment

Adjustment after Replacing the PCU and/or the Development Unit

Turn ON the main power.

Do the "Automatic Color Calibration (ACC)" for the copier mode & printer mode as follows:

- "User Tools" icon > "Machine Features" > "Maintenance" > "Auto Color Calibration" > "Start"

- Print the ACC test pattern.

- Put the printout on the exposure glass.

- Put 10 sheets of white paper on the test chart. This ensures the precise ACC adjustment.

- Close the SPDF/ARDF or the platen cover.

- Press "Start Scanning" on the LCD. Then, the machine starts the ACC.

Exit the User Tools mode.

[*]IMAGING TEMPERATURE SENSOR (THERMISTOR)

Toner supply cooling fan unit (page 4-212)

Controller box (page 4-197)

Duct [A]

Connector [A]

Image Transfer Belt Unit (page 4-71)

PCDU (K) (page 4-58)

Imaging temperature sensor harness guide [A] and Imaging temperature sensor

×2).

Replacement and Adjustment

- When installing a complete brand-new PCDU, it is not necessary to set SP3-701: New Development Unit detection

[*]WASTE TONER

WASTE TONER BOTTLE

Before Replacing the Waste Toner Bottle

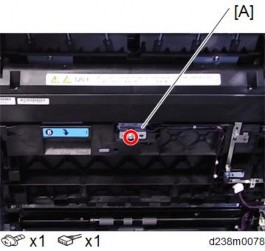

When the bottle is replaced after the machine detects that the waste toner bottle is full and stops, the counter for the Waste Toner Bottle is reset automatically.When the bottle is replaced before the machine stops due to a full bottle, it is necessary to reset the PM counter manually (set SP3-701-142 to “1” before replacing the bottle, then switch the power off).

SP3-701 (Manual New Unit Set)

This SP is the new unit detection flag.0: new unit detection flag OFF, 1: new unit detection flag ON

| Item | SP |

| Waste toner bottle | SP3-701-142 |

Replacement

Open the waste toner cover [A].

Pull out the waste toner bottle [A].

Replace the waste toner bottle.

Replacement and Adjustment

IMAGE TRANSFER UNIT

IMAGE TRANSFER BELT UNIT

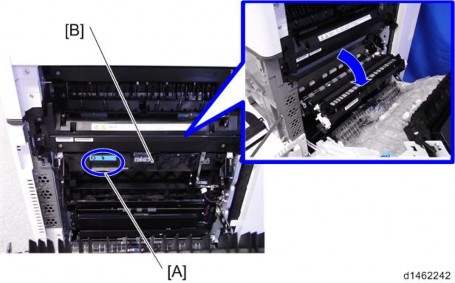

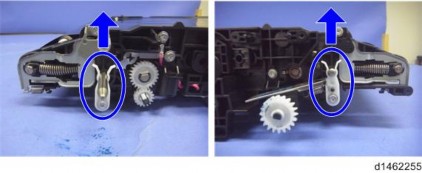

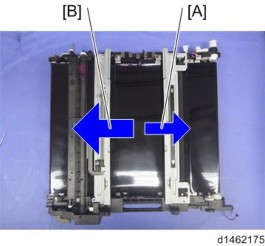

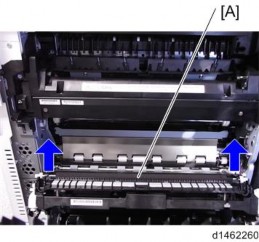

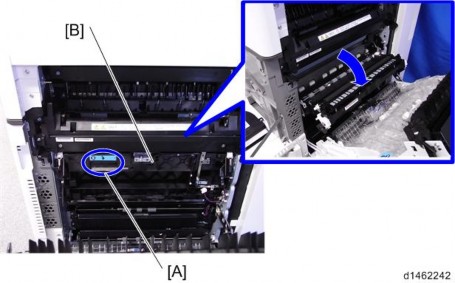

- Note that if the two levers [A] are not pointing up, the image transfer belt unit cannot be inserted.

[*]Before you remove or attach the image transfer belt unit, open the right door and the paper transfer unit.

[*]Do not touch the rollers but hold the upper/lower resin parts [A] when you lift the Image Transfer Unit. Touching the rollers may cause poor image quality.

[*]Precautions when attaching the image transfer belt unit:

- Slowly push the unit until it is inserted all the way, and then give a final strong push one more time. Then lock the ITB lock lever and ITB contact lever.

If the ITB contact lever is locked with the image transfer belt unit not fully inserted into the machine, the paper transfer roller is not set in the correct position when the

paper transfer roller unit is closed. This causes shadows on the image or paper jam, and the paper transfer roller unit may not open.

What to Do before Replacing the Image Transfer Belt

Before replacing the Image Transfer Belt unit, set SP3-701-093 to "1" and switch the power OFF. Then replace the Image Transfer Belt unit and switch the power ON.

SP3-701 (Manual New Unit Set)

This SP is the new unit detection flag.

0: new unit detection flag OFF, 1: new unit detection flag ON

Item SP Image Transfer Belt Unit SP3-701-093

Replacement

Open the front cover.

Image transfer front cover [A]

Release the lock [A] and open the right door .

Replacement and Adjustment

[*]Pull the handle [A] and open the paper transfer unit .

[*]Release the ITB lock lever [A] and ITB contact lever .

[*]Pull out the image transfer belt unit fully [A].

[*]Lift the handle to release the lock, and remove the image transfer belt unit.

Locking mechanism by handle

Replacement and Adjustment

- Slowly push the unit until it is inserted all the way, and then give a final strong push one more time. Then lock the ITB lock lever and ITB contact lever.

[*]IMAGE TRANSFER CLEANING UNIT

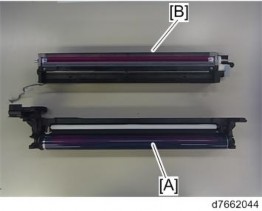

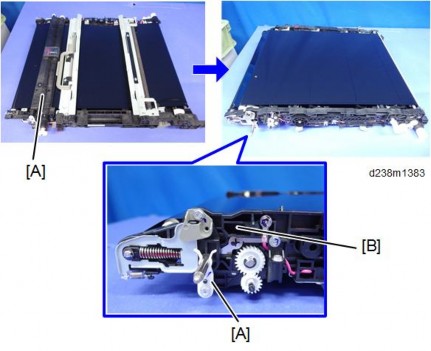

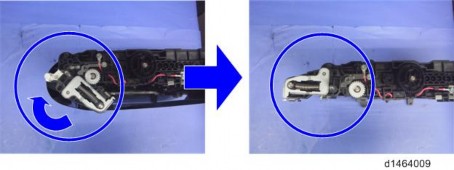

- Before removing the image transfer cleaning unit [A], turn the assembly upside down (as shown on the right), so that the image transfer cleaning unit [A] is underneath the image transfer belt unit . This prevents scattering of toner.

[*]When replacing the Image Transfer Cleaning Unit, do not touch the cleaning blade edge.

What to Do before Replacing the Image Transfer Cleaning Unit

Before replacing the Image Transfer Belt Cleaning, set SP3-701-102 to "1" and switch the power OFF.

Then replace the Image Transfer Belt Cleaning and switch the power ON.

SP3-701 (Manual New Unit Set)

This SP is the new unit detection flag.

0: new unit detection flag OFF, 1: new unit detection flag ON

Item SP Image Transfer Cleaning Unit SP3-701-102

Replacement

Image transfer belt unit (page 4-71)

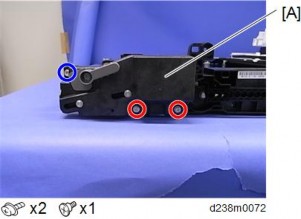

Image transfer lock unit [A]

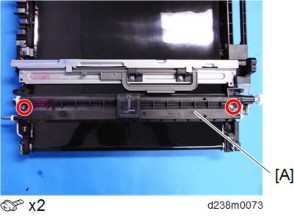

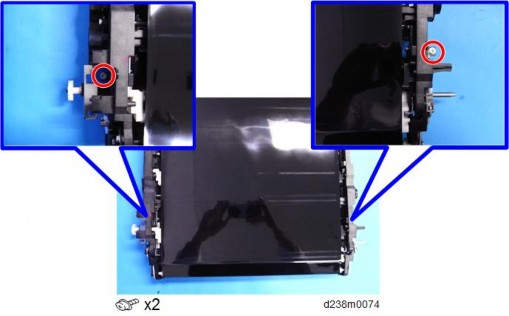

Remove the screws above the image transfer cleaning unit [A].

Replacement and Adjustment

Turn the whole image transfer belt unit over, and remove the screws below the image transfer cleaning unit.

While releasing the hook, lift the image transfer belt unit gently, and remove the image transfer cleaning unit.

Put toner on the image transfer belt.

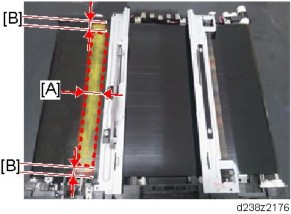

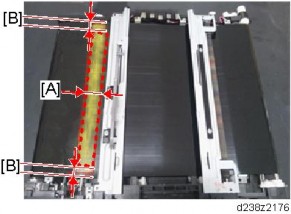

[A]: 20mm or more : About 5mm

- It is not necessary to specify the color of the toner, though yellow toner is used in the above example.

Attach the image transfer cleaning unit.

[*]Rotate the image transfer belt about 10mm [A] in the reverse direction, then turn it forward one complete turn .

[*]IMAGE TRANSFER BELT

- Do not touch the rollers but hold the upper/lower resin part [A] when you lift the Image Transfer Unit. Touching the rollers may cause poor image quality.

Image transfer belt unit (page 4-71)

Bracket [A]

Replacement and Adjustment

Brackets [A]

[*]Image transfer cleaning unit (page 4-75)

[*]Remove the tension fixing frames [A] and (front side: black, rear side: gray).

[*]Position the image transfer unit with the front side underneath.

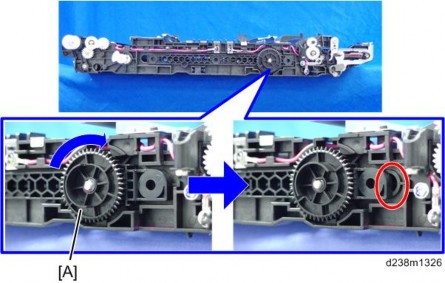

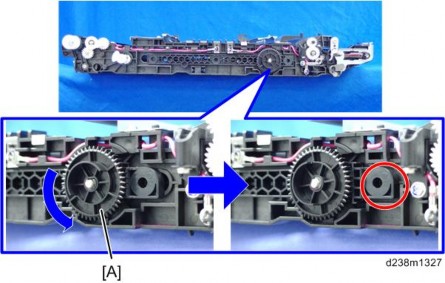

[*]Rotate the gear [A] to change to the OPEN position.

The part in the red circle opens.

[*]Release the tension, and remove the belt.

Replacement and Adjustment

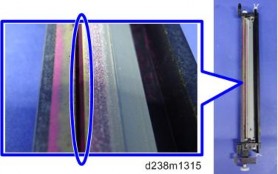

Attaching the Belt

- When attaching the belt, make sure that there is no foreign material on it.

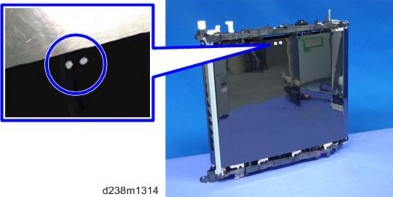

- Make sure to attach the belt with the edge with markings (2 white dots) at the unit’s rear.

- Be careful not to bend or scratch the belt.

Place the image transfer unit upright with its front face down, and then attach the belt from the top.

Make sure to have the belt’s edge with markings (2 white dots) positioned at the top (unit’s rear).

[*]Holding the resin parts on the top and bottom, place the unit on its side.

[*]Adjust the belt position according to the following two points:

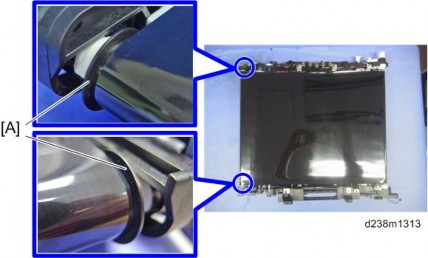

- The belt must be attached between the flanges [A] at both ends of the tension roller.

- The belt’s edge must be between the two lines on the frame.

[*]Apply tension back to normal.

Replacement and Adjustment

[*]Rotate the gear [A] to change to the CLOSED position.

The part in the red circle closes.

[*]Attach the tension fixing frames [A] and (front side: black, rear side: gray).

[*]Put toner on the image transfer belt.

[A]: 20mm or more : About 5mm

- It is not necessary to specify the color of the toner, though yellow toner is used in the example above.

Attach the image transfer cleaning unit. (Refer to page 4-75)

[*]Rotate the image transfer belt about 10mm [A] in the reverse direction, then turn it forward one complete turn .

[*]Attach the brackets [A]

[*]Attach the bracket [A]

[*]Attach the image transfer lock unit [A].

Replacement and Adjustment

[*]Install the image transfer unit on the machine.

Adjustment after replacing the Image transfer belt

After replacing the image transfer belt, to prevent twisting of the belt, pass the belt round once in the direction of the arrow.

[*]PAPER TRANSFER ROLLER

Open the right door.

Pull the handle [A] and open the paper transfer unit .

[*]Paper transfer roller [A]

Replacement and Adjustment

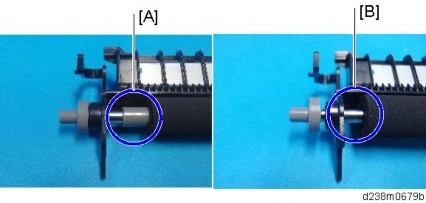

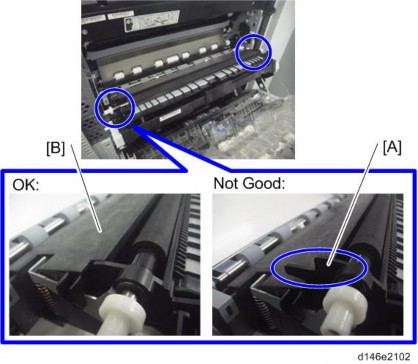

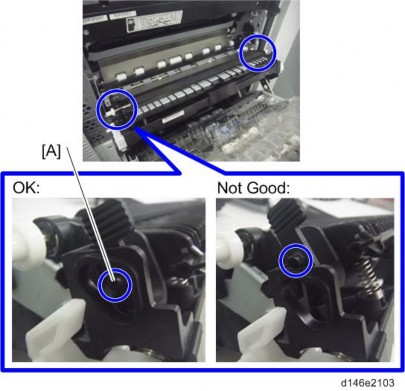

When reinstalling the paper transfer roller

When reinstalling the paper transfer roller, do not install the wrong type of roller.

[A]: Standard roller

: Imageable Area Extension Unit Type M19

When attaching the paper transfer roller, make sure that the roller is set in the correct position while referring to the three points described below.

- If the paper transfer roller is set incorrectly, the following problems may occur.

- Damage to the image transfer belt

- Roller detachment when opening and closing the paper transfer roller unit to remove a paper jam

- The paper transfer roller unit does not open

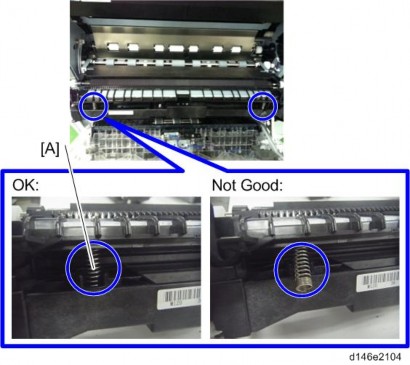

[*]Check that the pin [A] on either end of the paper transfer roller is inserted correctly.

[*]Check that the spring [A] at either end of the paper transfer roller unit is in the correct position at each end.

- If the paper transfer roller is set incorrectly, the following problems may occur.

Replacement and Adjustment

[*]PAPER TRANSFER ROLLER UNIT

What to Do before Replacing the Paper Transfer Roller Unit

Before replacing the Image Paper Transfer Roller Unit, set SP3-701-109 to "1" and switch the power OFF. Then replace the Image Paper Transfer Roller Unit and switch the power ON. SP3-701 (Manual New Unit Set)

This SP is the new unit detection flag.

0: new unit detection flag OFF, 1: new unit detection flag ON

Item SP Paper Transfer Roller Unit SP3-701-109

Replacement

Open the right door.

Remove the right clip ring and connector on the rear side.

Pull the handle [A] and open the paper transfer unit .

[*]Remove the left clip ring at the front side, and remove the paper transfer roller unit [A].

- Note that the sizes of the clip ring differ on the left and right.

- When attaching a paper transfer roller unit, first attach the bushings [A] to the paper transfer roller unit.

Replacement and Adjustment

[*]FUSING ENTRANCE SENSOR

Open the right door.

Fusing entrance sensor unit [A]

Fusing entrance sensor [A]

[*]TM/ID SENSOR

Before Replacing the TM/ID sensor

Each sensor assembly has a list of characteristic values attached to it. Before you replace the TM/ID sensor, you must do the following procedure, or process control/MUSIC will not be done correctly after power is switched on (it will use the values for the old sensor).

- The characteristic values attached to the service part must be entered before replacement. It is recommended that in case Process control/MUSIC after replacement is not completed successfully, take a note of values of SP3-333, SP3-334 and SP3-335.

- Note that if the two levers [A] are not pointing up, the image transfer belt unit cannot be inserted.

[*]Note the characteristic values that are listed on the bar code label.

- TM/ID Sensor (front): F, TM/ID Sensor (center): C, TM/ID Sensor (rear): R, be careful.

Turn on the main power switch, and then go into the SP mode.

[*]Input the characteristic values.

Input data for TM/ID Sensor: F into SP3-333. Input data for TM/ID sensor: C into SP3-334. Input data for TM/ID sensor: R into SP3-335.

| SP No. | Classification 1 | Classification 2 | Value |

| 3-333-001 | ID.Sens TestVal:F | K2: Check | TM/ID sensor: F, value of [1] |

| 3-333-002 | ID.Sens TestVal:F | Diffuse Corr | TM/ID sensor: F, value of [2] |

| 3-333-003 | ID.Sens TestVal:F | Vct_reg Check:Slope | TM/ID sensor: F, value of [3] |

| 3-333-004 | ID.Sens TestVal:F | Vct_reg Check:Xint | TM/ID sensor: F, value of [4] |

| 3-333-005 | ID.Sens TestVal:F | Vct_dif Check:Slope | TM/ID sensor: F, value of [5] |

| 3-333-006 | ID.Sens TestVal:F | Vct_dif Check:Xint | TM/ID sensor: F, value of [6] |

| 3-334-001 | ID.Sens TestVal:C | K2: Check | TM/ID sensor: C, value of [1] |

| 3-334-002 | ID.Sens TestVal:C | Diffuse Corr | TM/ID sensor: C, value of [2] |

| SP No. | Classification 1 | Classification 2 | Value |

| 3-334-003 | ID.Sens TestVal:C | Vct_reg Check:Slope | TM/ID sensor: C, value of [3] |

| 3-334-004 | ID.Sens TestVal:C | Vct_reg Check:Xint | TM/ID sensor: C, value of [4] |

| 3-334-005 | ID.Sens TestVal:C | Vct_dif Check:Slope | TM/ID sensor: C, value of [5] |

| 3-334-006 | ID.Sens TestVal:C | Vct_dif Check:Xint | TM/ID sensor: C, value of [6] |

| 3-335-001 | ID.Sens TestVal:R | K2: Check | TM/ID sensor: R, value of [1] |

| 3-335-002 | ID.Sens TestVal:R | Diffuse Corr | TM/ID sensor: R, value of [2] |

| 3-335-003 | ID.Sens TestVal:R | Vct_reg Check:Slope | TM/ID sensor: R, value of [3] |

| 3-335-004 | ID.Sens TestVal:R | Vct_reg Check:Xint | TM/ID sensor: R, value of [4] |

| 3-335-005 | ID.Sens TestVal:R | Vct_dif Check:Slope | TM/ID sensor: R, value of [5] |

| 3-335-006 | ID.Sens TestVal:R | Vct_dif Check:Xint | TM/ID sensor: R, value of [6] |

Replacement and Adjustment

Replacement procedure

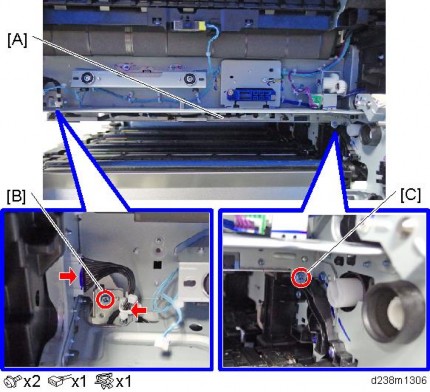

Image transfer belt unit (page 4-71)

Paper transfer roller unit (page 4-89)

Fusing unit (page 4-129)

TM/ID sensor unit [A]

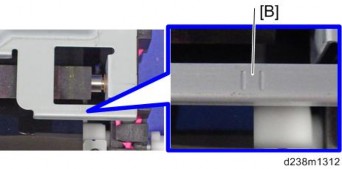

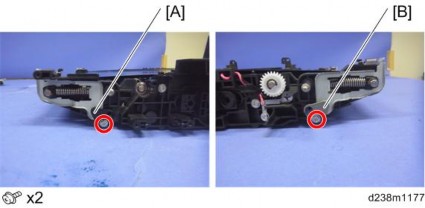

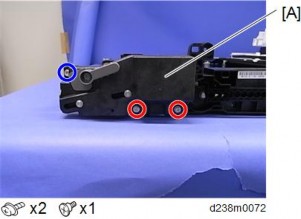

- When installing the TM/ID sensor unit.

- 1. Attach the screw of the front side

[*]2. Attach the screw of the back side [C]

[*]When installed in reverse order, an SC may occur because the sensor position has shifted.

[*]Disconnect the connectors.

[*]TM/ID sensor [A]

Replacement and Adjustment

Adjustment after Replacing the TM/ID sensor

Turn on the main power switch, and then go into the SP mode.

Run SP3-011-004 (Manual Procon: Exe Full MUSIC).

- If the SP3-011-004 can't finish successfully, make sure you are entering the correct value into the SP.

Related SPs

- SP3-011-004 (Manual ProCon :Exe: Full MUSIC) Executes Process Control and full MUSIC.

- SP3-012-001 to 010 (ProCon OK?: Front)

Displays the past 10 Process Control result codes detected by the front TM/ID sensor. The code is 2 digits per color from the left, in the order of YMCK. - SP3-012-011 to 020 (ProCon OK?: Center)

Displays the past 10 Process Control result codes detected by the center TM/ID sensor. The code is 2 digits per color from the left, in the order of YMCK. - SP3-012-021 to 030 (ProCon OK?: Rear)

Displays the past 10 Process Control result codes detected by the rear TM/ID sensor. The code is 2 digits per color from left, in the order of YMCK.

ProCon results code

Category Code Result name Description

00 and larger

00

Not executedFactory default setting (SP default) 10 and larger Result (Normal)

11

Succeeded

-

40 and larger ID Sensor

41ID sensor output error (Max)

Vt > Max42 ID sensor output error (Min) Vt < Min

43

ID Sensor error (Max)Development gamma is in target, but Vt value is less than upper limit.

44

ID Sensor error (Min)Development gamma is in target, but Vt value is less than lower limit. Category Code Result name Description

45 and larger ID Pattern detection45 ID Pattern extract error Cannot detect ID Pattern 50 Vmin_Bk/K2 error (Max) K:Vmin_Bk / CMY:K2 > Max 51 Vmin_Bk/K2 error (Min) K:Vmin_Bk / CMY:K2 < Min 52 K5 error (Max) K5 > Max 53 K5 error (Min) K5 < Min

54K5 calculated approximate point error K5 calculated approximate point

< Min

55Development gamma error (Max)

Development gamma > Max

56Development gamma error (Min)

Development gamma < Min

57Start developing voltage: Vk error(Max) Start developing voltage: Vk > Max

58Start developing voltage: Vk error(Min) Start developing voltage: Vk < Min

59

Not enough valid dataAdhesion amount data for development gamma calculation point is under 2.

90 and larger Result(End)

90

Potential not adjustedPotential control method is set as [0:FIX].

99

StoppedStopped by door open, power off, error. (Set when execute.)

- Execution result example (In order of YMCK from left)

- Factory default (SP default): [00,00,00,00]

- Starting adjust: [99,99,99,99]

- Fail Vsg adjust(Y): [21,99,99,99]

- Error of Development gamma Max(C): [99,99,55,99]

- Succeeded: [11,11,11,11]