HOME PAGE | < Previous | Contents | Next >

Detailed Descriptions

Detailed Descriptions

Detailed Descriptions

7.8 TONER SUPPLY

7.8.1 OVERVIEW

No. | Description | No. | Description |

1 | Toner bottle drive motor | 4 | Toner end sensor |

2 | Agitator | 5 | Toner supply motor |

3 | Sub-hopper |

Toner is supplied by a Hi-Act (High Accuracy and Clean Toner) cartridge + sub-hopper.

7.8.2 MECHANISM

Toner Supply (Toner Cartridge - Sub-hopper)

When the toner cartridge is set, the transport nozzle on the side of the unit is inserted into the bottle (Hi-Act system).

When the toner supply motor drives and the piezoelectric sensor in the sub-hopper detects there is no toner, the bottle drive motor rotates. The rotation of the bottle drive motor is transmitted to a transport coil via a drive gear, and toner in the bottle is transported horizontally. Due to the coil transport, stable toner supply/enhanced supply precision/reduction of residual toner are achieved.

Toner Supply

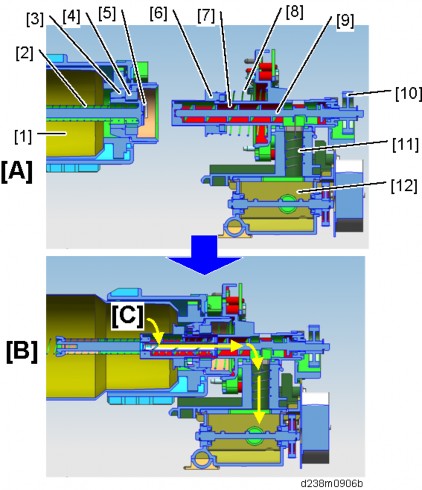

[A]: Before setting [B]: After setting [C]: Toner path

No. | Description | No. | Description |

1 | Toner bottle | 7 | Transport nozzle |

2 | Coil spring | 8 | Coil spring |

3 | Shutter holder | 9 | Toner transport coil |

4 | Seal | 10 | Drive gear |

5 | Shutter | 11 | Rocking spring |

6 | Shutter | 12 | sub-hopper |

Toner transported by the coil falls directly into the sub-hopper via the transport pipe.

To prevent toner from remaining, the rocking spring in the transport pipe moves up and down together with the coil.

Detailed Descriptions

Detailed Descriptions

Detailed Descriptions