HOME PAGE | < Previous | Contents | Next >

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

2.1.2 MECHANISM

Paper Feed Separation Mechanism

Paper feed is an RF paper feed system. The paper feed unit comprises a pick-up roller, feed roller and friction roller. These rollers are high durability.

In the RF system, paper separation is assisted by the resistance of a separation roller with a torque limiter (reverse drive is not performed).

Drive Mechanism

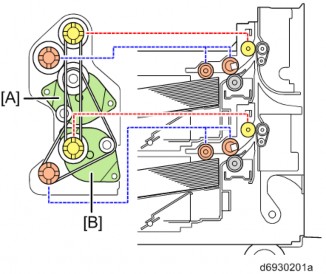

The pick-up roller and feed roller are driven by the paper feed motor [A]. The transport roller is driven by the transport motor [B]. The friction roller is not driven.

Friction Roller/Pick-up Roller Release Mechanism

When the paper feed tray is set, the friction roller comes in contact with the feed roller, and the pick-up roller contacts the uppermost sheet of paper.

However, when the paper feed tray is pulled out, to prevent paper from dropping out, the contact between the feed roller and friction roller, and between pick-up roller and paper is released.

Paper Feed Transport Mechanism

In this MFP, to maintain a fixed clearance between sheets, a paper feed sensor is provided near the pickup roller, which adjusts the paper feed timing.

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

1. The paper feed motor turns ON, and supplies the first sheet.

2. To prevent the next sheet from being fed, the pick-up solenoid switches ON just before the trailing edge of the first sheet leaves the pickup roller, and the pickup roller separates from the paper surface.

3. Slightly before the trailing edge of the first sheet leaves the paper feed roller, the paper feed motor switches OFF.

However, at this time, when the paper feed sensor detects no sheet (when the second sheet is not fed to the paper feed sensor position), pre-feed is performed without switching the paper feed motor OFF.

Pre-feed is as follows.

1. The pickup solenoid switches OFF, and the second sheet of paper is fed to the paper feed sensor position.

2. When the trailing edge of the second sheet passes the feed roller, the paper feed motor is switched OFF. The pickup solenoid remains OFF.

4. Just when the trailing edge of the first sheet passes the paper feed roller, the pickup solenoid is switched OFF, and the pickup roller is brought in contact with the paper surface.

5. When the first sheet is fed a predetermined distance by the downstream transport roller, the paper feed motor is switched ON to supply the second sheet.

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

Tray Base Plate Lift

When the paper feed tray is set in the main unit, the set switch switches ON, and it is detected that the tray is set. At this time, the coupling of the lift motor engages with the shaft at the rear of the tray, the motor rotates, and the tray base plate is lifted up. The paper surface pushes up the Pickup roller, the tray base plate is lifted until the upper limit sensor switches OFF (blocked), and the machine enters the standby mode.

When the paper feed tray is removed, the coupling is disengaged, and the base plate descends. At this time, the lift motor rotates until the coupling returns to the home position.

No. | Description | No. | Description |

1 | Lift motor | 3 | Tray rear side shaft |

2 | Coupling | 4 | Tray base plate |

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

No. | Description | No. | Description |

1 | Upper limit sensor | 2 | Pick-up roller |

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

Paper size detection

The end fence interlocks mechanically with the size detection actuator, and when the end fence is moved, the size detection actuator also moves.

When the paper feed tray is set, 4 size detection switches switch ON/OFF depending on the position of the size detection actuator. Paper size is detected by the detected combination of these switches.

No. | Description | No. | Description |

1 | End fence | 3 | Size detection actuator |

2 | Paper size switch | 4 | Tray set switch |

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

Paper size switch operation

Paper size | Paper size switch | |||

SW4 | SW3 | SW2 | SW1 | |

SRA3 (12”×18”) | 1 | 0 | 1 | 0 |

A3 (DLT) | 0 | 1 | 0 | 0 |

B4 (LG) | 0 | 0 | 1 | 1 |

0 | 1 | 1 | 1 | |

A4_SEF | 1 | 1 | 1 | 0 |

LT_SEF | 1 | 1 | 0 | 0 |

B5_SEF | 1 | 0 | 0 | 0 |

A4_LEF (LT_LEF) | 0 | 0 | 0 | 1 |

B5_LEF (Exe_LEF) | 0 | 0 | 1 | 0 |

A5_LEF | 0 | 1 | 0 | 1 |

Paper Feed Unit PB3220 (D787-17)/PB3210 (D787-18, -22)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

PAPER FEED UNIT PB3210/PB3220 (D787)

Remaining paper detection/paper end detection

Remaining paper detection

Detection of paper remaining in the paper feed tray is performed by a combination of ON/OFF (contact/non-contact) of contact-type remaining detection plates (printed circuits) CN-3, CN-5. When the amount of remaining paper decreases, and the tray lift motor rotates, the remaining paper sensors CN-3 and CN-5 in the motor are turned ON/OFF.

The following 4 levels of remaining paper can be detected:

Amount remaining | 100% | 70% | 30% | 10% |

CN-3 | OFF | ON | ON | OFF |

CN-5 | OFF | OFF | ON | ON |

Control panel remaining paper display | 4 bars | 3 bars | 2 bars | 1 bar |

Paper end detection

When the paper feed tray is empty, the paper end sensor switches ON (unblocked) due to the end feeler.

No. | Description | No. | Description |

1 | Paper end sensor | 3 | Slot in the tray base plate |

2 | End feeler |