HOME PAGE | < Previous | Contents | Next >

ARDF DF3090 (D779)

ARDF DF3090 (D779)

ARDF DF3090 (D779)

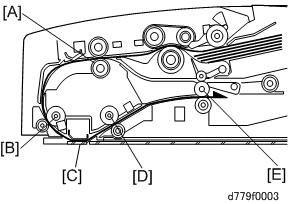

Skew Correction Mechanism / Registration Mechanism

Skew Correction

This machine adjusts paper skew by hitting the originals against the pullout roller [A].

The skew correction sensor [B] detects the leading edge of the original after it passes through the separation area. When the leading edge reaches the entrance transport roller, the paper is fed a bit more so that it bumps into the pullout roller [A], to make slack for skew adjustment.

Registration Mechanism

The registration sensor [C] detects the leading edge of the originals. The machine uses the data for registration during copying.

A | Pullout Roller |

B | Skew Correction Sensor |

C | Registration Sensor |

D | Original Width Sensor |

E | Sheet-through Exposure Glass |

Transport Mechanism (Simplex)

Originals are transported by the pullout roller [A] and the entrance transport roller [B] to the sheet-through exposure glass [E], which scans the image. After this process, the originals are transported to paper exit section by the exit transport roller [D] and the exit driven roller [E].

ARDF DF3090 (D779)

Description | |

A | Pullout Roller |

B | Entrance Transport Roller |

C | Sheet-through Exposure Glass |

D | Exit Transport Roller |

E | Exit Driven roller |

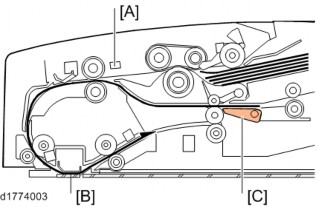

Transport Mechanism (Duplex)

When originals are detected by the skew correction sensor [A], the transport motor switches OFF and the original stops for a while. After skew correction, the originals are re-transported to the sheet-through exposure glass [B], which scans the first side (front). Then the inverter solenoid switches ON and the junction gate [C] opens. By that process, the originals are transported to the reverse roller. At this time, the transport motor stops and the inverter solenoid switches off.

ARDF DF3090 (D779)

ARDF DF3090 (D779)

ARDF DF3090 (D779)

ARDF DF3090 (D779)

Description | |

A | Skew Correction Sensor |

B | Sheet-through Exposure Glass |

C | Junction Gate |

The originals, which reached the reverse roller, are re-fed over the upper surface of the junction gate [A]. When the originals reach the sheet-through exposure glass [B], the second side (back) is scanned.

To make the order of the sheets on the exit tray correct, the two sides (front/back) of the original need to be inverted. Therefore, the inverter solenoid switches ON and the originals are transported to the reverse roller again. After the inversion, the originals exit onto the exit tray [C].