HOME PAGE | < Previous | Contents | Next >

Internal Finisher SR3180 (D766)

* The home position is at “Junction gate: Upper-transportation position” and “Trailing edge presser: Pressure release position”, and is detected by the junction gate motor HP sensor.

Sub-scan direction (transport direction) jogger mechanism

Paper transported to the stacking area by the paper exit rollers is delivered to the reverse rollers. Paper alignment for the sub-scan direction is performed by using the reverse rollers to press the trailing edge of the paper against the guide fence.

Paper detection on the stack guide plate

The paper exit sensor detects paper when there is paper on the stack guide plate.

Sheet edge face alignment mechanism (main-scan direction)

Internal Finisher SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

INTERNAL FINISHER SR3180 (D766)

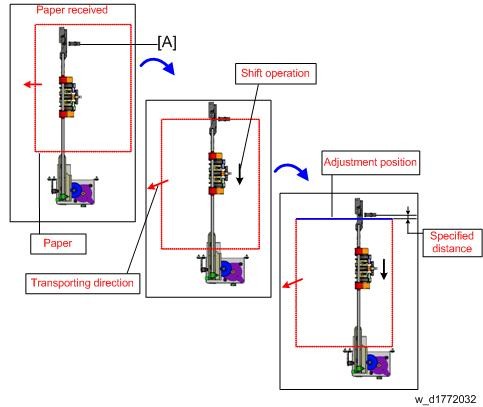

This option does not have a jogger. Paper position adjustment for stapling (main-scan direction) is performed by paper shift and alignment of the paper edges using the registration sensor.

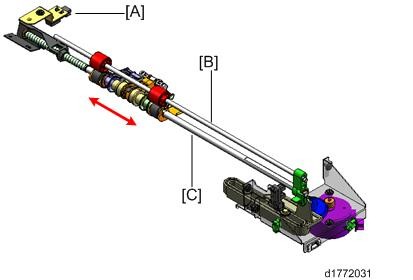

Paper transported to the shift rollers ([B] and [C]) is shifted when the trailing edge is 10mm from the paper exit roller. (Paper position is based on the entrance sensor, and is controlled by motor pulses.)

The paper shifts to a position where it can be detected by the sub-scan (leading edge) registration sensor [A]. The paper is then shifted for a specified distance. These operations are applied to each sheet, so that the edge of each sheet is aligned as shown by the blue line above.