Main Unit

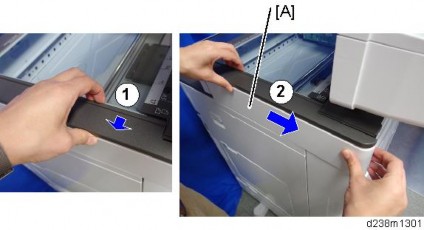

Upper left cover (page 9)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

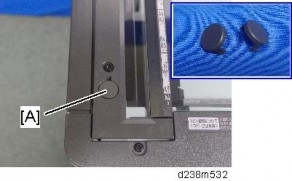

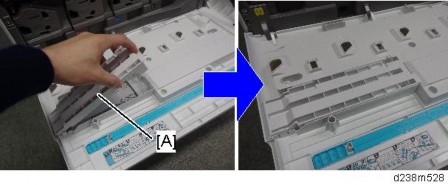

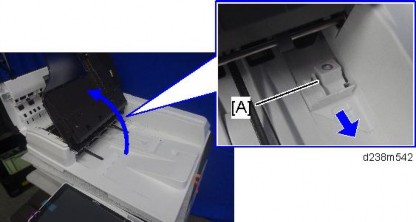

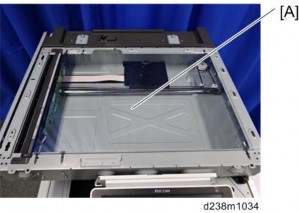

Paper exit guide HP sensor bracket [A] ![]() ×1)

×1)

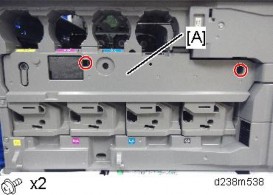

Paper exit guide drive motor [A] ![]() ×2,

×2, ![]() ×1)

×1)

Main Unit

Rear cover (page 4)

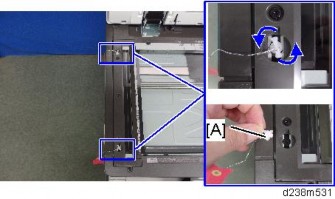

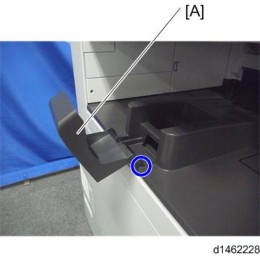

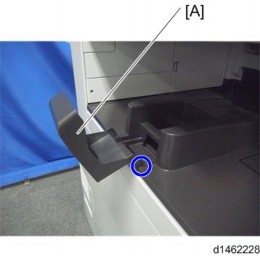

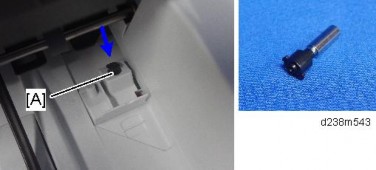

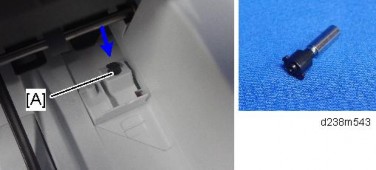

Feeler [A] ![]() ×1)

×1)

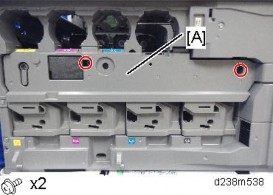

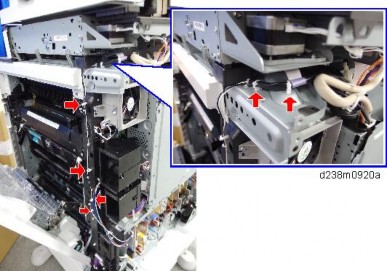

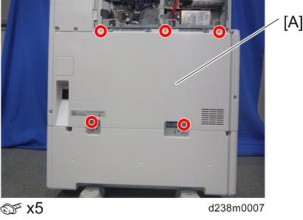

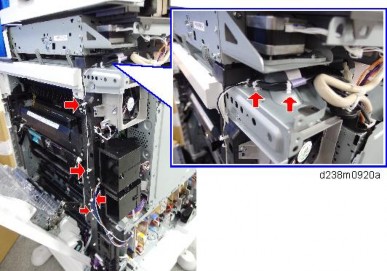

Controller board bracket [A] ( ×5,

×21,

×17, ground plate×1)

Paper bundle transport upper motor [A] ![]() ×2,

×2, ![]() ×1)

×1)

D3B8/D3B9

27

SM

Main Unit

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Main Unit

Inner cover (page 2)

Front left cover (page 4)

Booklet stapler unit (page 49)

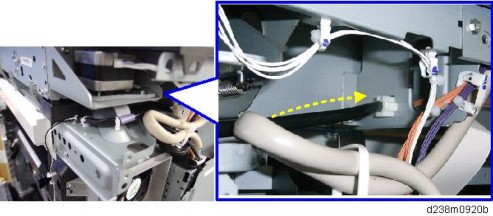

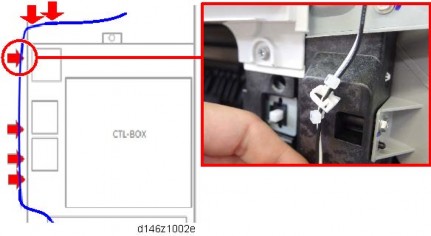

Harness guide [A] ![]() ×2,

×2, ![]() ×6) (SR3210 only)

×6) (SR3210 only)

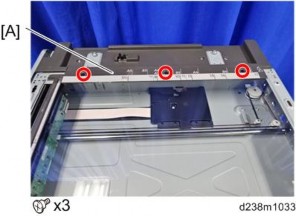

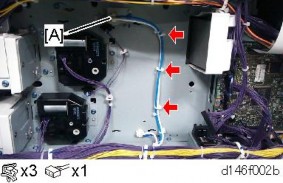

Paper exit transport motor bracket [A] ![]() ×3,

×3, ![]() ×1)

×1)

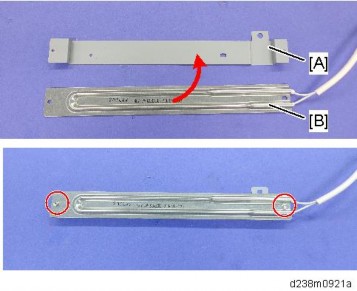

Reverse roller (front) [A], reverse roller (rear) [B]

Main Unit

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Be careful not to damage the shape of the hook enclosed by the blue circle when removing the reverse rollers.

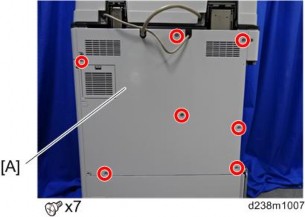

Stapler tray [A] ![]() ×7,

×7, ![]() ×2,

×2, ![]() ×1)

×1)

Main Unit

Stapler tray (page 28)

Stapler tray paper sensor bracket ![]() ×1)

×1)

Stapler tray paper sensor [A] ![]() x1,

x1, ![]() x1,

x1, ![]() x1)

x1)

Main Unit

Stapler tray (page 28)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Paper bundle transport upper pressure release HP sensor [A] ![]() ×1)

×1)

Stapler tray (page 28)

Feedout pawl HP sensor [A] ![]() ×1)

×1)

Main Unit

Stapler tray (page 28)

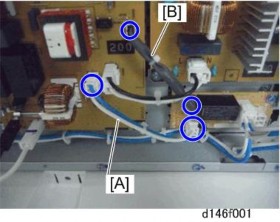

Separate the jogger fence [A] from the jogger HP sensor [B].

Jogger HP sensor ![]() ×1)

×1)

Release and remove the tab with a small driver, etc.

Stapler tray (page 28)

Jogger motor [A] ![]() ×2,

×2, ![]() ×1)

×1)

Main Unit

Stapler tray (page 28)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Paper bundle transport upper pressure release motor [A] ![]() ×2,

×2, ![]() ×1)

×1)

Main Unit

Stapler tray (page 28)

Feedout Pawl motor bracket [A] ![]() ×2,

×2, ![]() ×1,

×1, ![]() ×2)

×2)

Feedout Pawl motor [A] ![]() ×2)

×2)

Stapleless Stapler Unit/Stapler Unit (SR3210)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Rear cover (page 4)

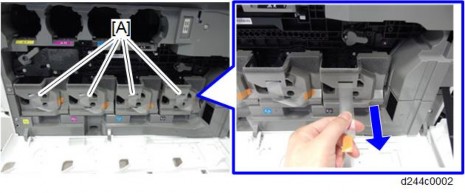

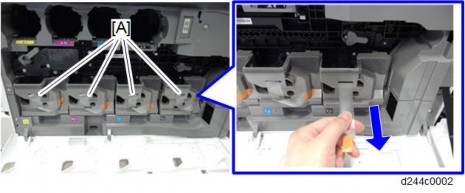

Stapleless stapler unit [A] ![]() ×2,

×2, ![]() ×1,

×1, ![]() ×2)

×2)

Stapleless Stapler Unit/Stapler Unit (SR3210)

Inner cover (page 2)

Inner middle cover [A] ![]() ×2)

×2)

Paper Guide Drive Motor with Bracket [A] ![]() ×2,

×2, ![]() ×1)

×1)

Unhook the spring of the stapler unit.

Stapleless Stapler Unit/Stapler Unit (SR3210)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Bracket [A] and harnesses ![]() ×1,

×1, ![]() ×1,

×1, ![]() ×2)

×2)

Bracket [A], Stapler unit [B] ![]() ×2)

×2)

Stapleless Stapler Unit/Stapler Unit (SR3210)

1. Move the stapleless stapler [A] to the recess.

Stapleless stapler transfer motor [A] ( ×2,

2. ×1)

Move the stapleless stapler to the recess. (page 38 "Stapleless Stapler Transfer Motor")

Stapler transfer motor [A] ![]() ×2,

×2, ![]() ×1)

×1)

Stapleless Stapler Unit/Stapler Unit (SR3210)

Inner cover (page 2)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Bracket [A] ![]() ×1)

×1)

Paper guide drive motor [A] ( ×2,

×1)

3.

Stapleless Stapler Unit/Stapler Unit (SR3210)

Move the stapleless stapler to the recess. (page 38 "Stapleless Stapler Transfer Motor")

Stapleless stapler HP sensor bracket [A] ![]() ×1)

×1)

Stapleless stapler HP sensor [A] ![]() ×1)

×1)

Stapleless Stapler Unit/Stapler Unit (SR3210)

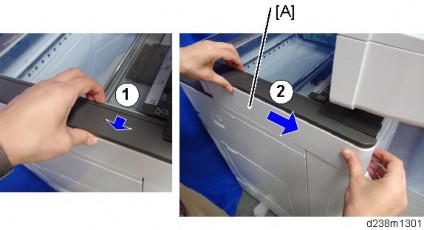

Open the front cover.

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Inner middle cover [A] ![]() ×2)

×2)

Bracket [A] ![]() ×1)

×1)

Stapler HP sensor [A] ![]() ×1)

×1)

Stapleless Stapler Unit/Stapler Unit (SR3210)

Rear cover (page 4)

Paper guide HP sensor [A] ![]() ×1,

×1, ![]() ×1, hook ×2)

×1, hook ×2)

Booklet Stapler Unit (SR3220)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Open the front cover, and then remove two knobs [A] ![]() x1 for each)

x1 for each)

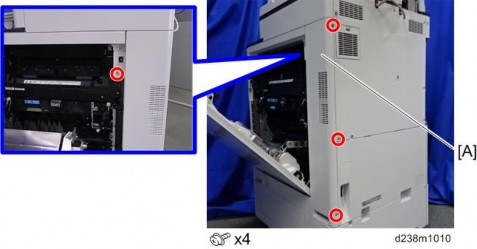

Booklet stapler unit cover [A] ![]() x4,

x4, ![]() x1)

x1)

Stopper [A] ![]() ×2)

×2)

Disconnect three connectors and one clamp at the rear side of the booklet stapler unit.

Booklet Stapler Unit (SR3220)

Pull out the booklet stapler unit, and then release three clamps.

Bring the stapler unit [A] near the center.

Small guide plate [A]

Booklet Stapler Unit (SR3220)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Guide plate [A]

Stapler cartridge [A]

Cover [A] ( ×2)

Booklet Stapler Unit (SR3220)

Stapler unit (clincher side) [A] ![]() ×3,

×3, ![]() ×2)

×2)

Disconnect three connectors and release four clamps on the stapler unit (driver side).

Stapler unit (driver side) [A] ![]() ×3,

×3, ![]() ×4)

×4)

Attach the special tool* to the stapler unit to adjust the staple position of the stapler unit.

Check that four pins ([A] and [B]) on the special tool are fixed in the slots [C] on the stapler unit as shown below.

Booklet Stapler Unit (SR3220)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

[A]: Two pins for driver [B]: Two pins for clincher

*Use the following part numbers to get the special tool

HOLDER FLONT(B7936410)

HOLDER: REAR (B7936420)

ROD: CLAMP (B7936431)

ADJUSTING SCREW: M4 (B7936432)

-or-

B7936400 STAPLER:SERVICE PARTS ASSY

Tighten the wing screw [A] on the special tool to secure the stapler and special tool.

Tighten the screws completely to secure the clincher side [A] of the stapler ![]() ×3).

×3).

Booklet Stapler Unit (SR3220)

Loosen the wing screw to remove the special tool.

Reattach all the removed parts.

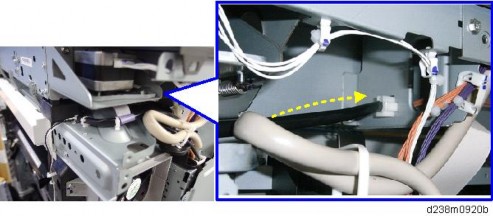

Make sure that the harnesses [B] are routed behind the resin part [A]. Otherwise, the harnesses block the route of the stapler, which causes a stapler transfer motor error.

Check that the stapler works properly.

All staple patterns must be checked.

If there are any problems with the clincher, adjust the staple position with the special tool again.

Booklet Stapler Unit (SR3220)

Rear cover (page 4)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

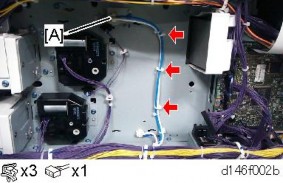

Remove the connectors of controller board [A] ![]() ×9,

×9, ![]() ×2,

×2, ![]() : ground plate×1)

: ground plate×1)

Stopper [A] ![]() ×2)

×2)

Front cover (page 1)

Pull out the booklet stapler unit [A].

Booklet stapler unit ![]() ×2)

×2)

When you remove the booklet stapler unit from the main frame, be careful not to catch the cable on the frame.

Booklet Stapler Unit (SR3220)

Booklet stapler unit (page 49)

Knobs [A] ![]() ×2)

×2)

Booklet stapler unit cover [A] ( ×4,

×1)

3.

4. Remove connectors ( ×1, ×4, ×4, ground plate×1)

Booklet Stapler Unit (SR3220)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

5. Bracket [A] ![]() ×1,

×1, ![]() ×3,

×3, ![]() ×1)

×1)

6. Center-folding unit [A] ![]() ×5)

×5)

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

Center-folding tray paper exit sensor bracket [A] ![]() ×1,

×1, ![]() ×1)

×1)

Center-folding tray paper exit sensor [A]

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Trailing edge stopper transport sensor bracket [A] ![]() ×2,

×2, ![]() ×1,

×1, ![]() ×4)

×4)

Trailing edge stopper paper surface sensor [A] ![]() ×1)

×1)

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

Trailing edge stopper HP sensor [A] ![]() ×1)

×1)

Center-folding unit (page 50)

Center-folding blade HP sensor [A] ![]() ×1)

×1)

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Center-folding cam HP sensor bracket [A] ![]() ×1,

×1, ![]() ×2)

×2)

Center-folding cam HP sensor [A] ![]() ×1)

×1)

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

Trailing edge stopper motor [A] ![]() ×2,

×2, ![]() x1)

x1)

Center-folding unit (page 50)

Folding blade motor [A] ![]() ×2)

×2)

Booklet Stapler Unit (SR3220)

Center-folding unit (page 50)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Folding transport motor [A] ![]() ×2)

×2)

Booklet Stapler Unit (SR3220)

Pull out the booklet stapler unit (page 49 "Booklet Stapler Unit")

Booklet tray full sensor bracket [A] ![]() ×2,

×2, ![]() ×2,

×2, ![]() ×2)

×2)

Booklet tray full sensor 1 [A], 2 [B]

Booklet Stapler Unit (SR3220)

Controller board bracket (page 26 "Paper Bundle Transport Upper Motor (SR3220)")

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Stapler transfer motor (Mid.) [A] ![]() ×2,

×2, ![]() ×1)

×1)

Damper [A] ![]() ×2)

×2)

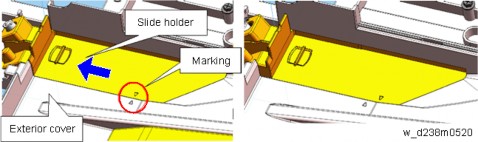

Attach it in the correct orientation as shown below.

Booklet Stapler Unit (SR3220)

Controller board bracket (page 26 "Paper Bundle Transport Upper Motor (SR3220)")

Paper bundle transport lower pressure release HP sensor bracket [A] ![]() ×1,

×1, ![]() ×1)

×1)

Paper bundle transport lower pressure release HP sensor [A]

Boards

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

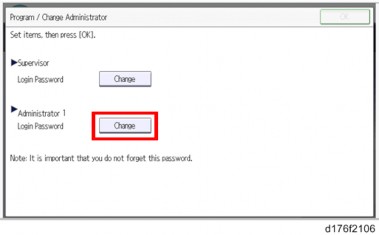

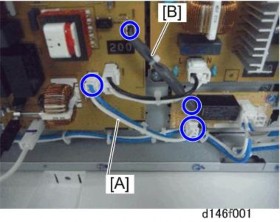

Make sure to set the SP provided on the metal plate of the main controller board after replacing the main controller board.

An EEPROM [A] is installed in the controller board to record the drive frequency and number of sheets. When the controller board is replaced, take the EEPROM off the old board and install it on the new one.

There is an EEPROM on the new main controller board, but this is not needed and can be discarded or kept as a spare part.

Rear cover (page 4)

Main controller board [A] ![]() ×4,

×4, ![]() ×23) SR3220

×23) SR3220

Boards

SR3210

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

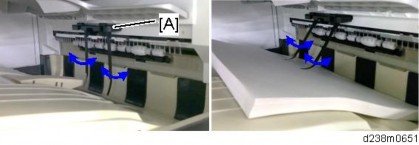

Overview

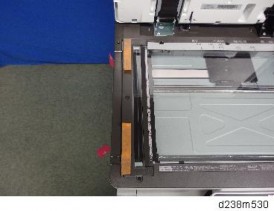

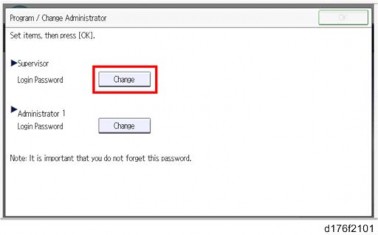

To achieve stable stacking of printouts and to prevent users from touching the printouts, paper exit guide [A] and paper exit guide cover [B] have been added.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Drive

With the paper exit guide drive motor [A] and the timing belt, the paper exit guides on both sides move at the same time.

Home position is detected by the paper exit guide HP sensor [B].

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Location of the stapleless stapler unit

The stapleless stapler unit [A] is on the same shaft as the conventional stapler unit [B], which uses staples.

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

The stapleless stapler unit is at the back and the conventional stapler unit is at the front. A spacer [C] on the shaft functions as a stopper, preventing the units from colliding.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Paper stack mechanism for stapling

The maximum thickness of the stack is 50 sheets for the conventional stapler, and 5 sheets for the stapleless stapler.

In order for the stapleless stapler to stack the paper smoothly, cam [C] and paper guide [B] adjusts the gap [A] of the stapler tray [E].

The cam [C] controlled by the paper guide motor [D] pushes the paper guide [B] down during the stapleless staple operation.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Stapleless stapler unit movement mechanism

The stapleless stapler transfer motor [A] moves the stapleless stapler unit to the stapling position from its home position when stapling with the stapleless stapler.

The home position is detected by the stapleless stapler HP sensor [B].

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

The stapler transfer motor [C] and the stapler HP sensor [D] are attached to the base plate.

There is a gap at the paper guide when the stapleless stapler unit is at the home position when stapling with the conventional stapler.

Because of this, paper will be guided with the paper guide [B] which works together with the lever [A] when the stapleless stapler unit moves to its home position.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Stapleless Stapler mechanism

The staple operation in this option applies a crimping method. V-shaped teeth press the sheets, applying a pressure of 220 kg.

This option performs two stapling operations for a single stapling operation as follows. [Moving to the first stapling position =>Stapling => Moving to the second stapling position => Stapling => Moving back to the home position]

Stapling is done by engaging the pressure cam [D] to stretch the pressure link [A], which applies pressure between to the upper tooth [C] and the lower tooth [B]. Moving and stapling operation for the stapler are driven by the stapler drive motor. The home position is detected by the stapleless stapler HP sensor.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Double/Single

The bond strength depends on the degree of entwining of fibers between sheets of the paper bundle. Setting to Single or Double stapling allows you change the bond strength. Single applies one staple operation.

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Double applies one more, with the same operation as the first staple, at 4mm from the first. The stapleless stapler drive motor moves the paper after the first stapling.

Bundle ejection

After stapling, the trailing edge presser is released. The bundle of paper is ejected by the paper output roller.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Stapler movement mechanism

This stapler needs to staple twice for a single staple position, and must be moved to do this stapling.

A cam [A], which is located in the stapler unit and has a groove on the body, and a securing pin perform the moving operation when stapling.

The moving and stapling is done by the stapleless stapler drive motor [B] and the home position is detected by the stapler HP sensor [C].

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

Stapler movement process

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

The movement differs between Single and Double stapling.

[A]: Paper

[B]: Stapleless stapler unit [P1]: Pre-stapling position

[P2]: Stapling position 1 (Single) [P3]: Stapling position 2 (Double) [P4]: Home position

Single stapling operation

The stapleless stapler unit is at the home position before receiving paper.

The stapleless stapler unit moves to the pre-stapling position when starting a stapleless stapling job.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

After receiving the first sheet, the stapleless stapler unit moves from the Stapling Position 1 towards the rear by 2.2 mm. After stacking the sheets, stapling is performed. (Stapling Position 1)

When stapling on multiple copies, the stapleless stapler unit moves towards the front by 2.2 mm from the pre-stapling position after the paper is delivered.

When stapling on multiple copies, Steps 3 and 4 are repeated.

The stapleless stapler unit returns to the home position after completing the job.

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

FINISHER SR3210/ BOOKLET FINISHER SR3220 (D3B8/D3B9)

Double stapling operation

The stapleless stapler unit is at the home position before receiving paper.

The stapleless stapler unit moves to the pre-stapling position when starting a stapleless stapling job.

After receiving the first sheet, the stapleless stapler unit moves from the Stapling Position 1 towards the rear by 2.2 mm. After stacking the sheets, stapling is performed. (Stapling Position 1)

Booklet Finisher SR3220 / Finisher SR3210 (D3B9/D3B8)

The stapleless stapler unit moves further towards the rear by 4 mm and performs stapling. (Stapling Position 2)

When stapling multiple copies, the stapleless stapler unit moves towards the front by

6.4 mm from the pre-stapling position after the paper is delivered.

When stapling multiple copies, Steps 3 to 5 are repeated.

The stapler returns to the home position after completing the job.