![]()

Turn off the main power switch and unplug the machine before beginning any of the replacement procedures in this manual.

This manual uses the following symbols.

![]()

: See or Refer to

![]()

: Screws

![]()

: Connector

![]()

: Clip ring

![]()

: E-ring

1 Bin Tray BN3100 (D632)

1. Open the right door of the machine [A].

Remove the front right cover [A] ( x 1).

2.

Harness cover [A] ![]() x 1)

x 1)

Electrical Components

Disconnect the connector of the 1-bin tray [A] ![]() x 1).

x 1).

1-bin tray [A] ( x 2)

5.

1-bin sorter unit [A] ![]() x 1)

x 1)

1 Bin Tray BN3100 (D632)

Paper sensor cover [A] ![]() x 2)

x 2)

Paper sensor [A] ![]() x 1, hook)

x 1, hook)

1-bin tray ![]() p.1 "Paper Sensor")

p.1 "Paper Sensor")

1-bin sorter unit ![]() p.1 "Paper Sensor")

p.1 "Paper Sensor")

1-bin control board [A] ![]() x 1,

x 1, ![]() x 3)

x 3)

R EVI SIO N HIS TORY | ||

Page | Date | Added/ Updated/ New |

None | ||

TRAY COVER 1

TRAY MOTOR AND HALF TURN SENSOR BOARD 2

![]()

Turn off the main power switch and unplug the machine before beginning any of the replacement procedures in this manual.

This manual uses the following symbols.

: See or Refer to

: Screws

: Connector

: Clip ring

: Clamp

: E-ring

Tray Cover

1. Remove the tray cover [A] by pressing on the two pawls [B] on the left side of the cover.

When Attaching the Tray Cover –

![]()

The right side of the tray cover should be attached first.

Fit the pawls [C] on the shift tray.

Align the square [D] so that it fits into the groove in the underside of the tray cover and does not interfere with the attachment of the cover.

Internal Shift Tray SH3040/ SH3060 (D388/D633)

Complete the attachment by inserting the left side pawls [B] into place.

Tray Motor and Half Turn Sensor Board

Top cover ( p.1 "Tray Cover")

Slip disc [A]

Tray motor [B] ( x 1)

Half turn sensor board [C] ( x 1).

D388/D633 2 SM

R EVI SIO N HIS TORY | ||

Page | Date | Added/ Updated/ New |

None | ||

COVERS 1

EXTERIOR COVERS 1

UPPER TRAY, END FENCE 2

MAIN UNIT 3

UPPER TRAY LIMIT SENSOR, LIMIT SWITCH 3

POSITIONING ROLLER 4

PROOF TRAY EXIT SENSOR 5

UPPER TRAY HEIGHT SENSORS 1, 2 5

EXIT GUIDE PLATE, UPPER TRAY EXIT SENSOR 6

PROOF TRAY FULL SENSOR 7

FINISHER ENTRANCE SENSOR 7

PRE-STACK TRAY EXIT SENSOR 8

STAPLER UNIT 9

CORNER STAPLER 9

POSITIONING ROLLER 10

FOLD UNIT 11

FOLD UNIT 11

FOLD UNIT ENTRANCE SENSOR 13

FOLD UNIT EXIT SENSOR 14

STACK PRESENT SENSOR 15

FOLDING HORIZONTAL SKEW ADJUSTMENT (FOR B804 ONLY) 16

FOLD VERTICAL SKEW ADJUSTMENT (FOR B804 ONLY) 19

BOOKLET STAPLER UNIT 21

BOOKLET STAPLER 21

BOOKLET STAPLER MOTOR 22

To Reattach the Booklet Stapler Motor 23

COMPONENT LAYOUT 24

GENERAL LAYOUT 24

Paper direction 24

Proof tray 25

Upper tray 25

Pre-stack tray 25

Lower tray 25

ELECTRICAL COMPONENTS 26

Upper Area B804/B805 26

Lower Area B804/B805 27

Punch Unit B702 28

Stacker/Stapler - B804/B805 29

B804 Fold unit 30

SUMMARY OF ELECTRICAL COMPONENTS 31

DRIVE LAYOUT 41

JUNCTION GATES 42

PROOF MODE 42

SHIFT MODE 42

STAPLE MODE 43

PRE-STACKING 44

TRAY MOVEMENT MECHANISM 46

UPPER TRAY 46

LOWER TRAY (B804 ONLY) 48

CORNER STAPLING 51

STACKING AND JOGGING 51

STAPLER MOVEMENT 52

CORNER STAPLING 53

BOOKLET STAPLING (B804 ONLY) 54

BOOKLET PRESSURE MECHANISM 54

BOOKLET STAPLING AND FOLDING 55

Overview 55

BOOKLET STAPLING AND FOLDING MECHANISMS 61

UPPER TRAY OUTPUT 64

FEED OUT 64

FEED OUT STACKING 65

PUNCH UNIT B702 (FOR B804/B805) 66

OVERVIEW OF OPERATION 66

B803/B805/D373/D374/D636/D637 ii SM

Skew Correction before Punching 66

Punch Unit Position Correction 67

PUNCH MECHANISMS 69

Paper Position Detection 69

Punch Unit Movement 70

Punch Selection and Firing 71

PUNCH HOPPER MECHANISM 72

FINISHER JAM DETECTION 73

![]()

Turn off the main power switch and unplug the machine before beginning any of the replacement procedures in this manual.

This manual uses the following symbols.

: See or Refer to

: Screws

: Connector

: Clip ring

: E-ring

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Open the front door [D].

Small upper cover [A] ( x1)

Upper cover [B] ( x2)

Front door bracket [C] ( x1)

Front door [D]

Front left side cover [E] ( x2)

Cover [F]

Paper exit cover [G] ( x2)

Rear cover [H] ( x2)

1. Remove the rear cover. ( "Exterior Covers")

Support the tray [A] with your right hand.

Pull gear [B] toward you to release.

Slowly lower the tray until it stops.

Front side cover [C] ( x1)

Rear side cover [D] ( x1)

Upper tray [E] ( x1)

Tray bracket [F] ( x4, x1 shoulder screw )

End Fence [G]( x3)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Front door, front left side cover, rear cover, upper cover ( "Exterior Cover")

End fence ( "Upper Tray, End Fence")

Upper tray exit mechanism [A] ( x4, x3)

Upper tray limit sensor [B] ( x1, x1)

Upper tray limit switch [C] ( x2)

Open the front door [A].

Pull out the stapling unit [B].

Positioning roller [C] ( x1, timing belt x1)

Small upper cover ( "Exterior Cover")

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Proof tray exit sensor bracket [A] ( x1)

Proof tray exit sensor [B] ( x1)

Small upper cover, upper cover ( "Exterior Cover")

Upper tray paper height sensor bracket [A] ( x1)

Upper tray paper height sensor [B] – staple mode (S08) ( x1)

Upper tray paper height sensor [C] – non-staple mode (S09) ( x1)

Rear cover, Upper covers, Front door, Cover, Paper exit cover ( "Exterior Cover")

Inner cover [A] ( x2)

Exit guide plate [B] ( x1, Link and spring, x1, x1)

Upper tray exit sensor [C] (S6) ( x1)

Exit guide plate. ( "Exit Guide Plate, Upper Tray Exit Sensor")

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Guide plate [A] (hook x 2)

Sensor bracket [B] ( x1)

Proof tray full sensor [C] (S11) ( x1)

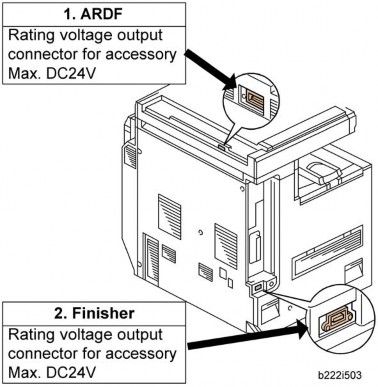

Disconnect the finisher if it is connected to the copier.

Sensor bracket [A] ( x1)

Finisher entrance sensor [B] (S1) ( x1)

Disconnect the finisher if it is connected to the copier.

Sensor bracket [A]

Pre-stack tray exit sensor [B] (S2)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Open the front door.

Pull out the stapler unit.

Inner cover [A] ( x3)

Stapler unit holder [B] ( x1)

Corner stapler [C] (M20) ( x1)

Open the front door [A].

Pull out the stapling unit [B].

Positioning roller [C] ( x1, timing belt x1)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Remove the back cover ( "Exterior Covers").

Open the front door.

![]()

The stapler unit is heavy.

Ground cable [A] ( x1)

Harness [B] ( x6, x6)

Stapler unit [C] ( x4)

![]()

Support the fold unit with your hand to prevent it from falling.

![]()

The fold unit is heavy.

Folding unit [D] ( x4, x2, x6)

If you have replaced the folding unit:

Read the DIP SW settings on the decal [A] attached to the back of the new folding unit.

Check the DIP SW settings on the main board [B] of the finisher.

If these settings are different, change these settings to match the settings printed on the decal attached to the folding unit.

![]()

Set DIP switches 1 to 4 (the switch set on the right). Do not touch the other DIP switches.

Pull out the stapler unit ( "Positioning Roller").

Fold unit entrance sensor bracket [A] ( x2)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Fold unit entrance sensor [B] (S26) ( x1, x1)

Open the front door.

Pull out the stapler unit ( "Positioning Roller").

Fold unit vertical guide plate [A]

Fold unit inner cover [B] ( x2, Spring pin x1)

Fold unit upper cover [C] ( x1)

Paper clamp mechanism [D] ( x4)

Fold unit exit sensor bracket [E] ( x1)

Fold unit exit sensor [F] (S31) ( x1)

![]()

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

If you intend to correct the horizontal and vertical skew for the fold unit at the same time, do those adjustments first, then replace the sensor. ( "Folding Horizontal Skew Adjustment" or "Fold Vertical Skew Adjustment")

Remove the stapler unit ( "Fold Unit")

Guide plate [A].

Stay [B] ( x4)

Left plate [C] ( x4)

Sensor bracket [D] ( x1)

Stack present sensor [E] (S32) ( x1)

![]()

The fold unit is adjusted for optimum performance before the finisher is shipped from the factory. Do this adjustment only if the edges of folded booklets are not even.

Switch the copier on and enter the SP mode.

Europe, Asia: Use SP6-134-001 (this is for A3 paper). North America: Use SP6-134-005 (this is for DLT paper).

![]()

If the original setting of SP6-134-001 or -005 is not "0", then you must do the vertical skew adjustment ( "Fold Vertical Skew Adjustment") after you finish this horizontal skew procedure.

Use the 10-key pad to input "-2" (mm) for the SP value. (Press to enter the minus sign.)

Press [#] then exit the SP mode.

Open the front door and pull the stapler unit [A] out of the finisher.

Open the guide plate [B].

Loosen the adjustment screw [C] and then tighten until it stops. (Do not over tighten.)

Remove the lock screw [D].

Raise the tip [E] of the adjustment screw very slightly and allow it to descend under its own weight.

Push the stapler unit into the finisher and close the front door.

Do a folding test.

Switch the copier on.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Put one page of A3 or DLT paper in the ARDF.

On the copier operation panel, select booklet stapling.

Press [Start]. One sheet is folded.

Remove the sheet from the lower tray.

Hold the folded sheet with the creased side pointing down and face-up (the same way that it came out of the finisher).

Referring to the diagram, determine if the skew is + [F] or - [G].

Open the front door of the finisher and pull the stapler unit [H] out.

Open the guide plate [I].

Turn the adjustment screw [J] to correct the amount of skew you measured from the test sheet.

For + skew [F], turn the adjustment screw (clockwise).

For – skew [G], turn the adjustment screw to the left (counter-clockwise).

Every click in the +/– direction adjusts the fold position by 0.1 mm by moving the bottom fence [K].

Raise the tip of the adjustment screw [J] and allow it to lower under its own weight.

Attach and tighten the lock screw [L].

Push the stapler unit into the machine, close the front door, then turn the copier on.

Europe, Asia: Do SP6-134-001 (this is for A3 paper). North America: Do SP6-134-005 (this is for DLT paper).

Reset it to "0".

Do the test again.

If the result is satisfactory, this completes the adjustment. -or- If some skew remains, repeat this adjustment.

![]()

After doing this adjustment, adjust for vertical skew, if necessary. ( "Fold Vertical Skew Adjustment")

![]()

The fold unit is adjusted for optimum performance before the finisher is shipped from the factory. Do this adjustment only if the edges of folded booklets are not even.

Switch the copier on.

Do a folding test.

Switch the copier on.

Put one page of A3 or DLT paper in the ARDF.

On the copier operation panel, select booklet stapling.

Press [Start]. One sheet is folded.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Hold the folded sheet with the creased side pointing down, and face-up (the same way that it came out of the finisher).

Referring to the diagram, determine if the skew is positive [A] or negative [B].

Measure the amount of skew.

Enter the SP mode

Europe, Asia: Use SP6-134-001 (this is for A3 paper).

North America: Use SP6-134-005 (this is for DLT paper).

Enter one-half the measured amount of skew. Example: If the measure amount of skew is

-1.2 mm, enter -0.6 mm

![]()

The range for measurement is –3.0 mm to +3.0 mm in 0.2 mm steps for every notch adjustment.

Exit the SP mode and do the test again (steps 2 to 5).

Repeat this procedure until the skew is corrected.

The illustration below shows the effects of +/- adjustment with SP6113. (The vertical arrows show the direction of paper feed.)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Open the front door.

Pull out the stapler unit ( "Positioning Roller").

Harness cover [A] ( x2)

Booklet stapler support stay [B] ( x4, x2, x4)

Stapler [C] ( x4)

Open the front door.

Remove the stapler unit. ( "Fold Unit")

3. Stay [A] ( x4).

Left plate [B] ( x4)

Harness cover [C] ( x2)

Booklet stapler support stay [D] ( x4, x2, x4)

Booklet stapler [E] ( x4)

Booklet stapler motor [F] ( x2, x1)

To Reattach the Booklet Stapler Motor

Reattach the booklet stapler motor.

![]()

Do not tighten the screws.

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Attach the special tool [A] and reattach the booklet stapler stay.

![]()

This tool is included with the stapler spare part.

Turn the gear [B] with your finger until it stops.

Tighten the screws to attach to the booklet stapler motor.

Remove the stay again and remove the special tool.

Reattach the booklet stapler stay.

Push the stapler unit into the machine.

Lower Tray (Booklet)*1

Folder Rollers*1

Folder Plate*1

Booklet Stapler*1

Upper Tray (Shift)

Proof Tray

Proof Tray Junction Gate

Punch Unit

Stapler Junction Gate

Pre-Stack Junction Gate

Pre-Stack Tray

Corner Stapler (M20)

*1: B804 Only

Paper direction

The operation of the proof tray and stapler junction gates direct the flow of the paper once it enters

the finisher:

Proof Junction Gate | Stapler Junction Gate | Paper Feeds |

Closed | Closed | Paper feeds straight through |

Open | Closed | Paper feeds to the proof tray |

Closed | Open | Paper feds to the staple tray |

Proof tray

Copies are sent to the proof tray (12) when neither sorting nor stapling are selected for the job.

Upper tray

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

The upper tray (11) receives copies that are sorted and shifted and also receives copies that have been corner stapled. Corner stapling is provided on both the B804 and the B805.

Pre-stack tray

The pre-stack tray has a switchback mechanism to increase the productivity of stapling. (

"Pre-Stacking) Pre-stacking is done for corner stapling in the B804/B805 and for booklet stapling in the B804.

Lower tray

The lower tray (7) receives copies that have been center folded and stapled (booklet stapling). Booklet stapling is not provided on the B805.

Upper Tray Limit Switch (SW2)

Stacking Roller HP Sensor (S13)

Stacking Sponge Roller Motor (M10)

Upper Tray Exit Sensor (S6)

Upper Tray Paper Height Sensor (S8) (Staple Mode)

Shift Roller HP Sensor (S5)

Shift Roller Motor (M18)

Exit Guide Plate Motor (M19)

Proof Junction Gate Solenoid (SOL1)

Upper Area B804/B805

Upper/Proof Exit Motor (M4)

Stapling Tray Junction Gate Solenoid (SOL2)

Upper Transport Motor (M2)

Exit Guide Plate HP Sensor (S7)

Proof Tray Exit Sensor (S10)

Proof Tray Full Sensor (S11)

Finisher Entrance Sensor (S1)

Upper Tray Paper Height Sensor (S9) (Non-Staple Mode)

Upper Tray Limit Sensor (S12)

Booklet Finisher & Finishers (B803/B805/ D373/D374/ D636/D637)

Lower Area B804/B805

Positioning Roller Motor (M14)

Lower Tray Full Sensor – Front (S34)*1

Lower Tray Full Sensor – Rear (S33)*1

Main Board (PCB1)

Upper Tray Full Sensor – (S20) *2

Upper Tray Full Sensor – (S19)

Booklet Stapler Board (PCB2)*1

Booklet Pressure Roller Solenoid – (SOL5)

*1

Upper Tray Lift Motor (M21)

Lower Transport Motor (M3)

Entrance Motor (M1)

Front Door Safety Switch (SW1)

Pre-Stack Tray Exit Sensor (S2)

Stapling Edge Pressure Plate Solenoid (SOL4)

Positioning Roller Solenoid (SOL3)

*1: B804 Only, *2: B805 Only

Punch Encoder Sensor (S24)

Punch Drive Motor (M24)

Punch HP Sensor (S24)

Punch Unit Board (PCB3)

Paper position sensor slide motor (M7)

Punch Unit B702

Paper Position Slide HP Sensor (S22)

Paper Position Sensor (S3)

Punch Hopper Full Sensor (S4)

Punch Movement Motor (M9)

Punch Movement HP Sensor (S21)

< Previous page: Part 25 | You are viewing page: Part 26 | Next page: Part 27 >